The 3-in-1 CNC Busbar Processing Machine integrates precision bending, punching, and cutting into one automated system. This all-in-one solution boosts productivity, ensures accuracy, and is ideal for manufacturing switchgear, transformers, and bus ducts. Get a high-efficiency China-made machine at a competitive price.

Fully-automatic Busbar Punching Bending Cutting Machine

Product Introduction:

Product details

Model: 503U-3-C

Power: 3×4Kw / 3×5.5Kw

Delivery time: 7-25 days

MOQ: 1 pcs

Certificate: ISO9001:2000/CE

Payment: T/T , L/C

Brand: LJMC

Place of region: Jinan, China

This machine is has three processing units of punching, cutting and bending. And it is designed with three independent hydraulic systems, so the punching, shearing, and bending unit can work simultaneously.

The machine realizes the automatic positioning of the three units, through the cooperates with each other of servo motor, PLC and touch screen.

Main Characters:

(1) The cutting length is automatically controlled by servo motor, the incision interface is flat, no waste, burrs and droop.

(2) No need to mark a proofing board for punching. Servo motor automatically locates punching coordinates. It supports continuous punching and punching with different apertures, and supports coordinate input and common template selection, which is convenient and efficient.

(3) The bending system automatically calculates the unrolling length of the copper busbar. High-precision screw guides control the bending length. The system has a variety of built-in bending processing templates; supports multi-segment and multi-angle continuous bending processing.

Processing units display

Cutting unit

Punching unit

Bending unit

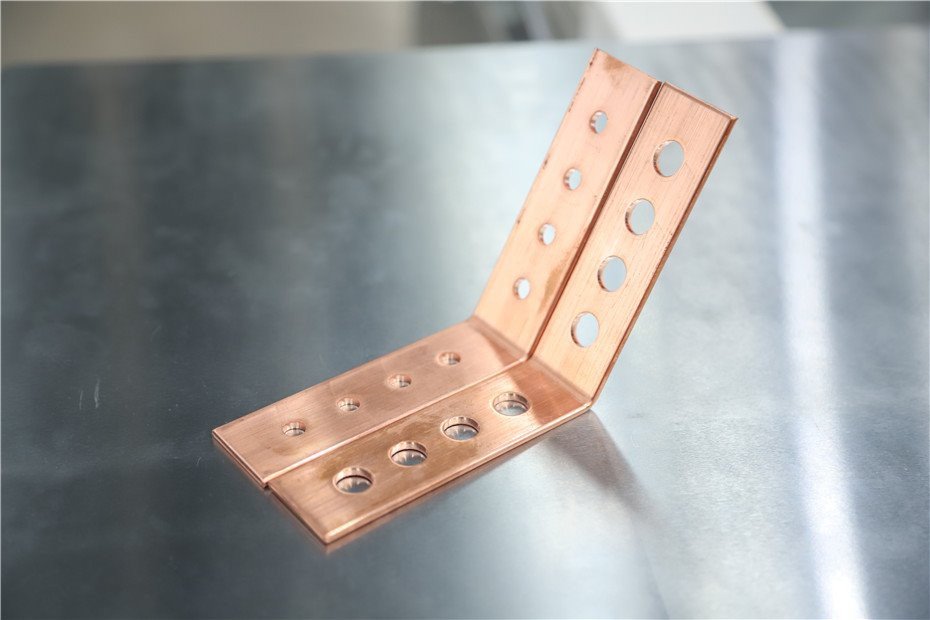

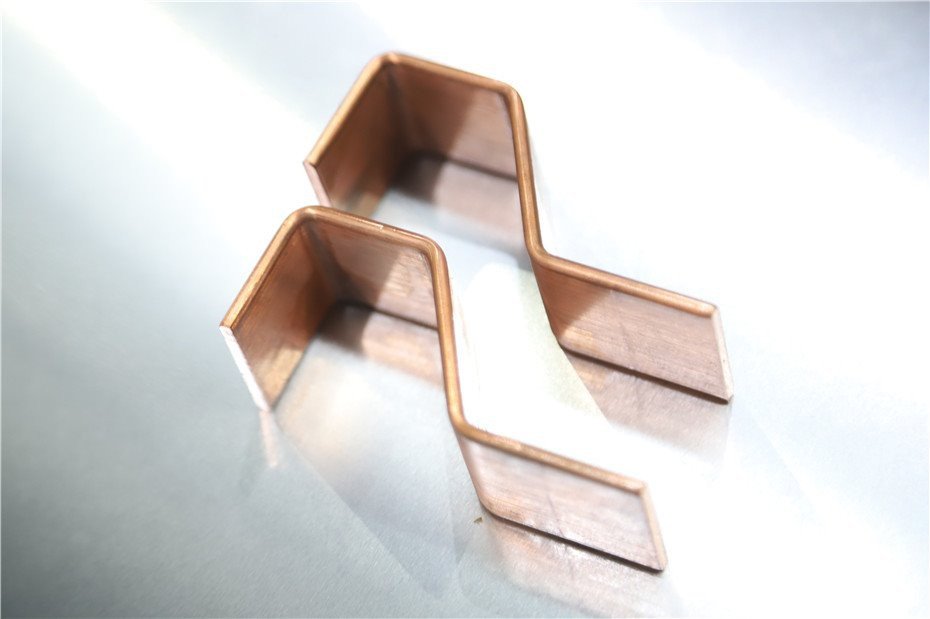

Processing samples display

| Item

| Model

| |

LTMC-303U-3-C | LTMC-503U-3-C | |

Nominal force (kn) | 300 | 500 |

Punching dia. range (mm) | Φ4.3~Φ25 | Φ4.3~Φ30 |

Max. thickness (mm) | 12 | 16 |

Max. width (mm) | 160 | 200 |

Number of servo axes | 4 | 4 |

Punching Y-axis stroke (mm) | 150 | 200 |

Punching X-axis stroke (mm) | 500 | 500 |

Cutting X-axis stroke (mm) | 1000 | 1000 |

Bending X-axis stroke (mm) | 500 | 500 |

Precision of block gauge (mm) | 0.2 | 0.2 |

Bending precision (degree) | ±1° | ±1° |

Repeat bending precision (degree) | ±0.5 | ±0.5 |

Power (kw) | 3×4kw | 3×5.5kw |

Outside dimension (mm) | 1850×1650×1340 | 2015×1815×1420 |

Total weight (kg) | 1500 | 1900 |

Hot Tags: cnc busbar machine, 3 in1 busbar machine, busbar bending machine, busbar punching machine, busbar cutting machine, copper busbar bending machine, cnc bending machine, cnc punching machine, bending machine, busbar machine, copper busbar machine, cutter machine, machine bending, China, suppliers, manufacturers, factory, price

LT Busbar Machine Videos:

FAQ for 503E-3-S / 503U-3-C Busbar Processing Machine

Q1: What functions does the 3-in-1 busbar machine provide?

A1: The machine combines punching, cutting, and bending functions in one unit. Each unit has an independent hydraulic system, allowing them to operate simultaneously.

Q2: What materials can the machine process?

A2: It is suitable for processing copper and aluminum busbars within the machine’s rated thickness and width.

Q3: What is the maximum busbar size the machine can handle?

A3: Depending on the model:

303U-3-C: max. 12 mm thickness, 160 mm width

503U-3-C: max. 16 mm thickness, 200 mm width

Q4: Does the machine support automatic positioning?

A4: Yes. The machine uses a servo motor, PLC, and touch screen to achieve automatic positioning for punching, cutting, and bending operations.

Q5: How is the cutting accuracy and surface quality?

A5: The cutting length is servo-controlled. The cutting surface is flat, without burrs, droop, or material waste.

Q6: Do I need a template or marking for punching?

A6: No. The servo system automatically positions the punching coordinates. It also supports continuous punching, mixed aperture punching, coordinate input, and template selection.

Q7: Does the machine support multi-angle or multi-segment bending?

A7: Yes. The machine automatically calculates busbar unrolling length and supports multi-segment and multi-angle continuous bending.

Q8: How many servo axes does the machine have?

A8: Both models (303U-3-C and 503U-3-C) have 4 servo axes.

Q9: What is the delivery time?

A9: The standard delivery time is 7–25 days, depending on order quantity.

Q10: What certificates does the machine have?

A10: The machine is certified with ISO9001:2000 and CE.

Q11: What payment terms are supported?

A11: T/T and L/C are accepted.

Q12: Where is the machine manufactured?

A12: The machine is produced in Jinan, China, by the LJMC brand.