The busbar processing machine is a versatile 2-in-1 CNC busbar processing machine that integrates precision bending, punching, and cutting functions into one efficient system. Designed for electrical manufacturing industries, it enables high-accuracy processing of copper and aluminum busbars used in switchgear, transformers, and power distribution equipment. This all-in-one solution enhances productivity, reduces handling time, and ensures consistent quality for busbar fabrication.

Turret Double Table Busbar Processing Machine

Product Description

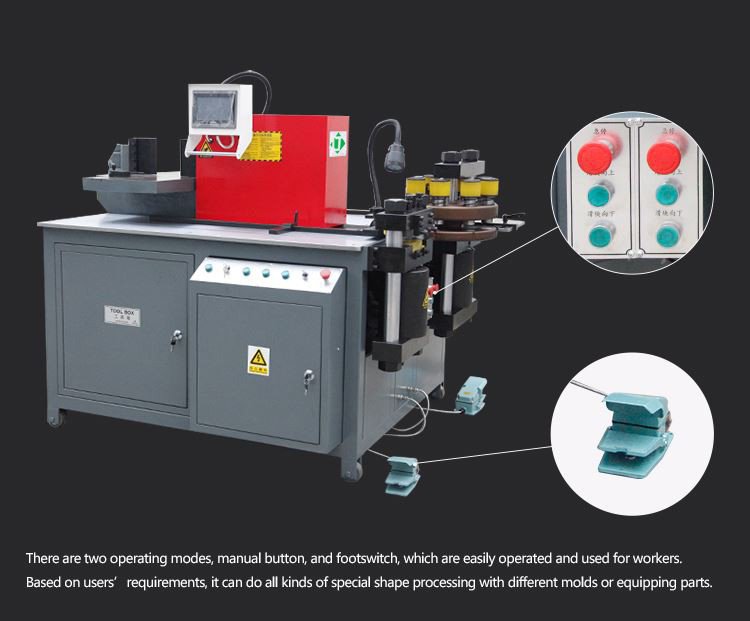

This series CNC busbar processing machine has three units: punching, shearing, and bending. It is easy to adjust each unit to shorten the processing time and improve production efficiency. It is used to process copper and aluminum busbars in different specifications. By relative operation unit, it can easily and quickly do all kinds of processing to copper and aluminum busbars, such as shearing, punching (circular hole and oblong hole), flat/horizontal bending, vertical bending, and knurling. Change different molds to do special processing to copper busbars, such as flat press, emboss, cable connector process, cut, flat crush, push, and bend.

Main Characteristics

1. The shearing unit uses sharp shearing, the incision interface is flat, no droop, no burrs, and no waste. Beautiful shape.

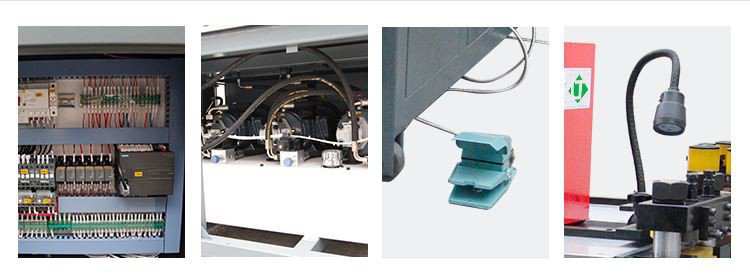

2. The punching unit uses a united eight-mode turnplate to make sure the upper lengthen the working life. No need to change molds frequently, labor intensity is highly reduced. It is easy and quick to use. Producing efficiency is obviously higher than a traditional one.

3. The bending station is a double-deck worktable, which ensures the three working stations can be operated at the same time without any interference. The bending station adopts an open structure, very convenient to pick out the processed copper busbar.

4. The machine has four casters so it is easy to be moved everywhere. There are two operating modes, manual button, and footswitch, which are easily operated and used for workers. Based on users’ requirements, it can do all kinds of special shape processing with different molds or equipping parts.

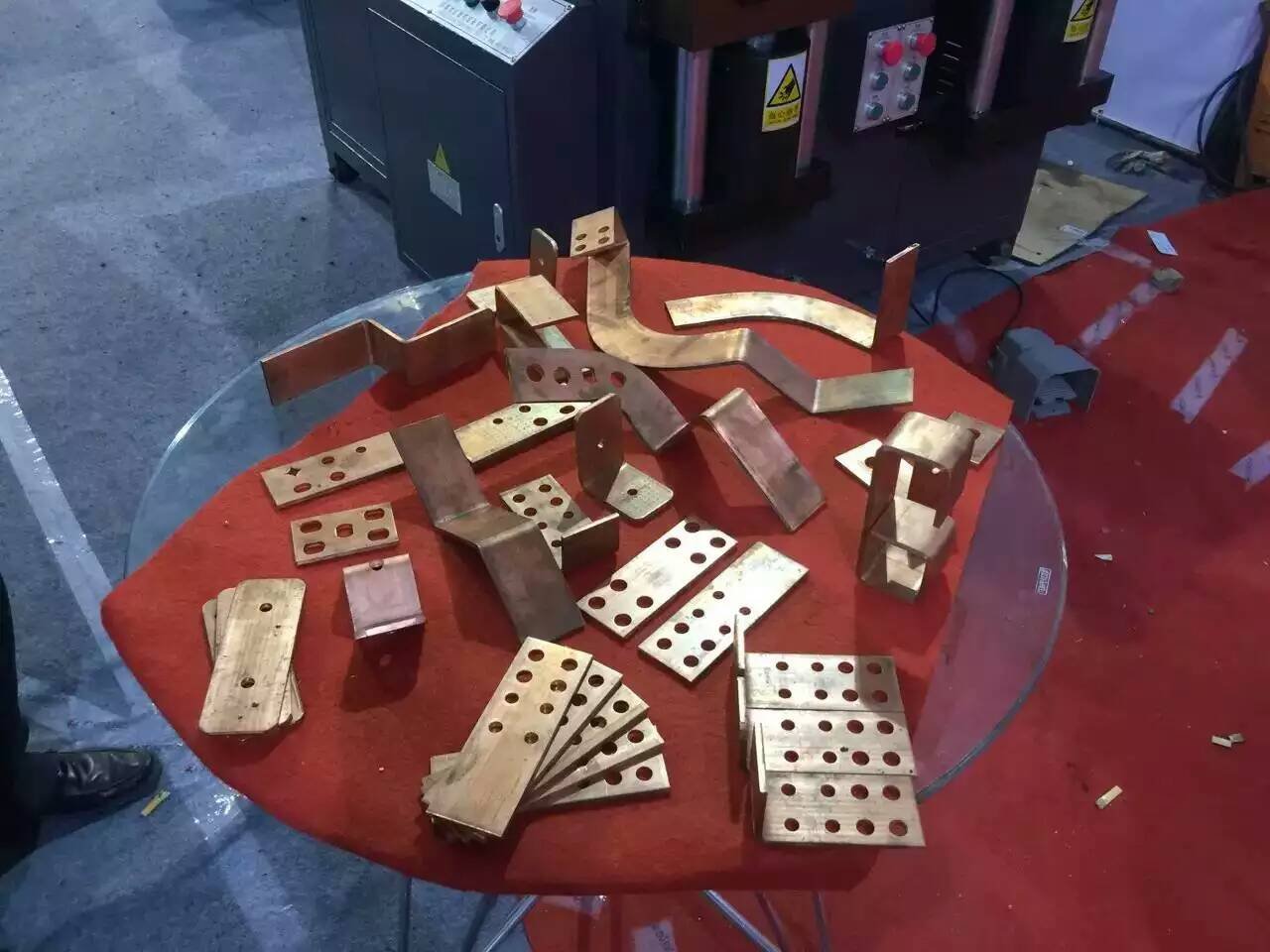

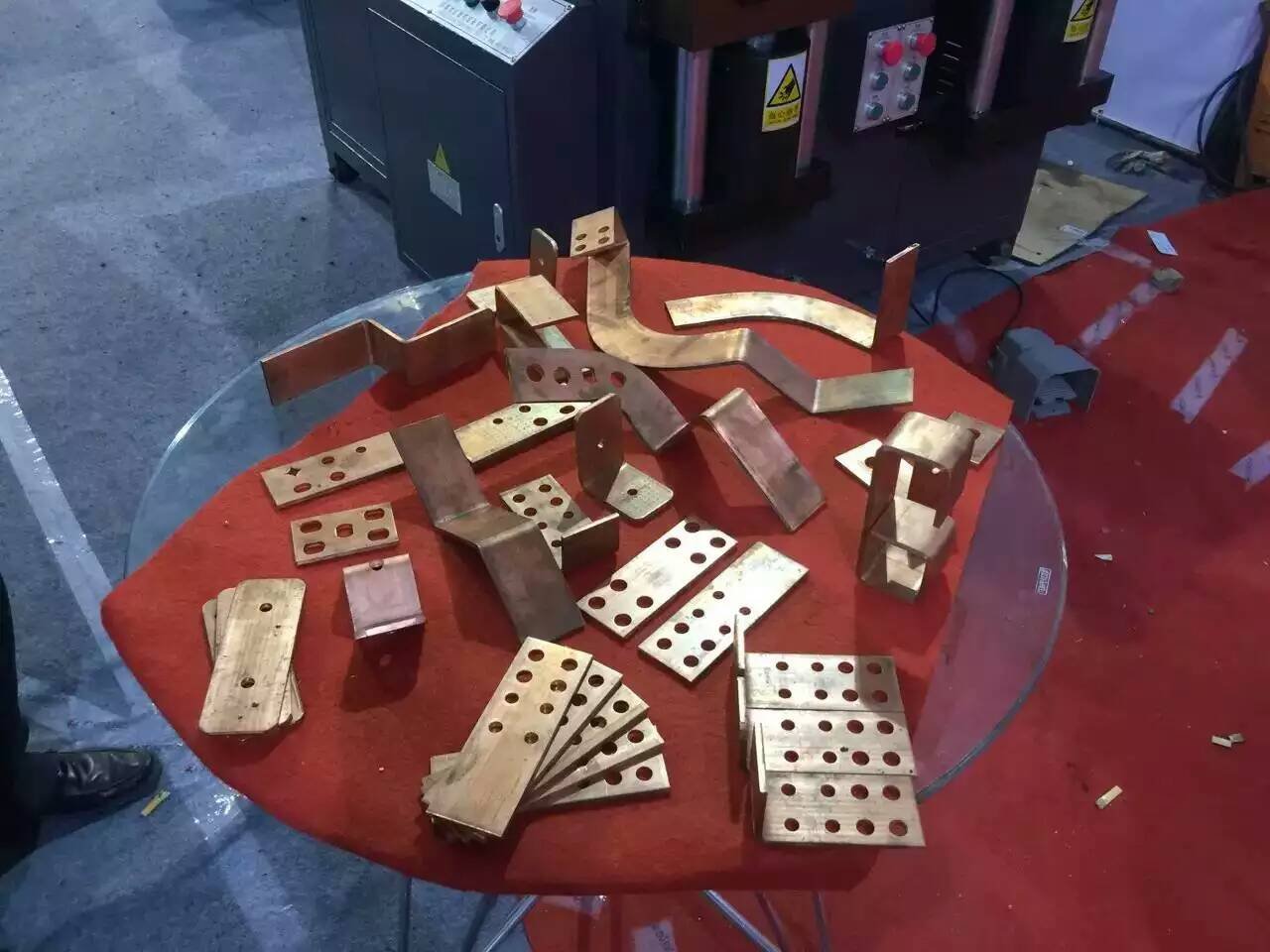

Processing Samples Display

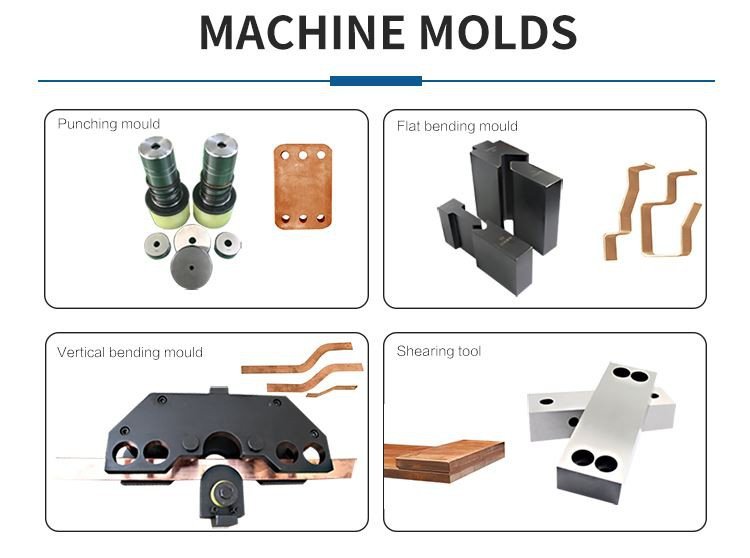

Machine Molds & Dies

If you are looking for busbar machine molds and dies, please clik the link.

We have hole punching molds, cutting molds, bending molds, and customized molds.

LTMC Certifications

Busbar Machine Packaging and Shipping

LT Busbar Machine Videos:

Turret Double Table Busbar Processing Machine FAQ

1. What is a turret double table busbar processing machine?

This machine is a multifunctional CNC busbar processor equipped with punching, shearing, and bending units. It is designed for efficient processing of copper and aluminum busbars with different specifications.

2. What types of operations can this machine perform?

It can complete shearing, punching (round and oblong holes), flat/horizontal bending, vertical bending, knurling, embossing, flattening, cable connector forming, pushing, and customized bending with different molds.

3. What are the main advantages of the punching unit?

The punching unit uses an 8-mode turret turnplate, reducing mold-changing frequency and improving efficiency. It extends mold life and significantly reduces labor intensity.

4. How does the shearing unit perform?

The shearing unit adopts a sharp-cutting system, ensuring smooth cutting surfaces without burrs, drooping, or material waste.

5. What is special about the bending station?

The double-deck worktable design allows three stations to operate simultaneously without interference. The open bending structure makes it easy to remove processed busbars.

6. Can the machine be moved easily?

Yes. The machine is equipped with four casters, allowing convenient movement within the workshop.

7. What operation modes are available?

Workers can choose between manual button control and footswitch control, depending on their workflow needs.

8. Can the machine work with customized molds?

Yes. Based on user requirements, the machine can be fitted with special molds for unique shapes and processing needs.

9. What types of molds and dies are available?

Available molds include hole punching molds, cutting molds, bending molds, embossing molds, and fully customized molds for special applications.

10. What industries commonly use this machine?

It is widely used in electrical switchgear manufacturing, power distribution equipment production, transformer workshops, and busbar fabrication centers.

11. Does the machine support mass production?

Yes. Its turret punching structure, double worktable bending design, and high-efficiency shearing system make it suitable for continuous and repetitive industrial production.

12. What materials can the machine process?

The machine is designed to process copper and aluminum busbars of various thicknesses and widths.

Hot Tags: turret double table busbar machine, CNC busbar processing machine, hydraulic busbar punching bending cutting machine

turret double table busbar machine, CNC busbar processing machine, hydraulic busbar punching bending cutting machine, 3-in-1 busbar fabrication machine, copper aluminum busbar working machine, busbar punching shearing bending machine, turret busbar punching machine, double-table busbar processor, CNC copper busbar equipment, industrial busbar forming machine, high-efficiency busbar workstation, multi-function busbar processing equipment, electrical switchgear busbar machine, power distribution busbar fabrication equipment, busbar workshop machinery, busbar hole punching equipment, busbar cutting and bending tool, heavy-duty hydraulic busbar machine, copper busbar customization machine, aluminum busbar fabrication solution, professional busbar processing tools, programmable CNC busbar system, automatic busbar sheet metal machine, copper bar punching and shearing equipment, switchgear copper busbar production machine, electric cabinet busbar processing line