LTHQ400-2000B CNC Busbar Bending Machine-the ultimate solution for high-precision, automated bending of copper and aluminum busbars. Designed for industrial applications in switchgear,transformers,and power distribution systems, this machine combines advanced servo motor technology, CAD/CAM integration, and a robust closed-bending structure to deliver unparalleled accuracy and efficiency.

HQ400-2000B CNC Copper Busbar Bending Machine

Description:

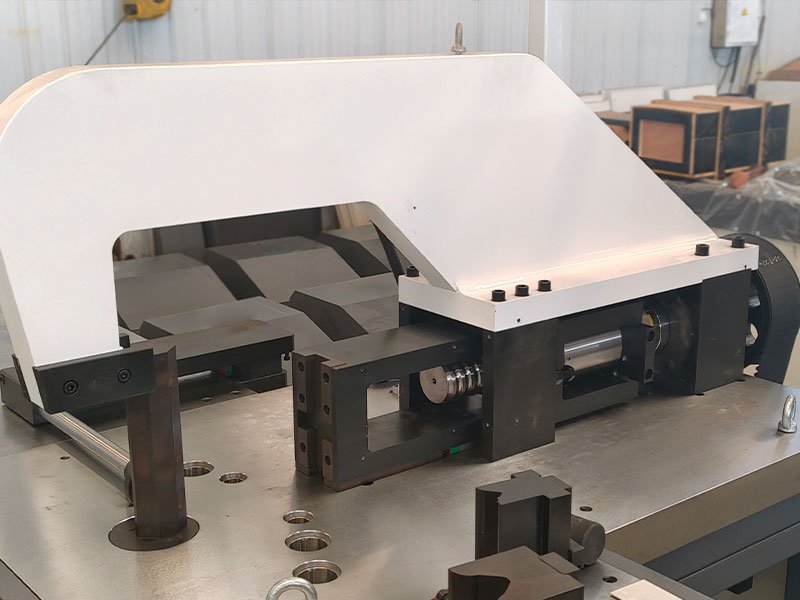

LT HQ400-2000B busbar machine is an automatic CNC busbar bending machine, used for bending copper and aluminum busbars.

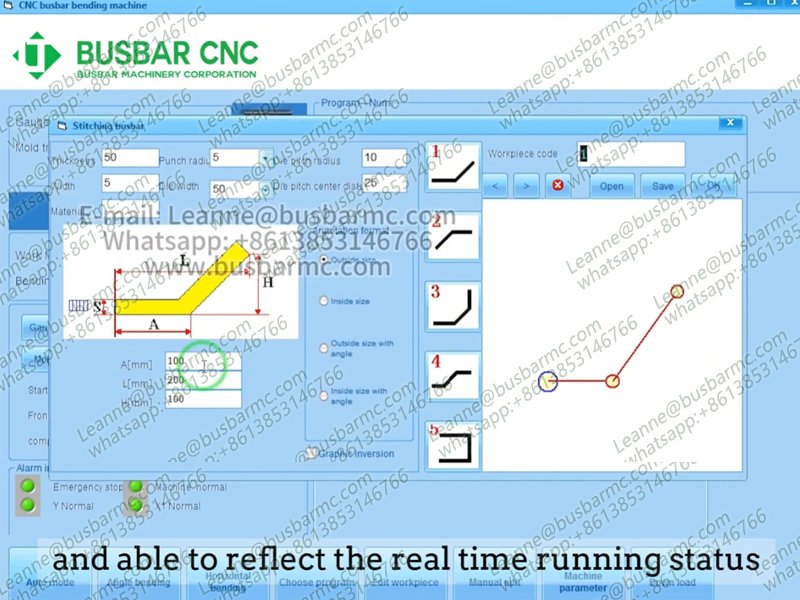

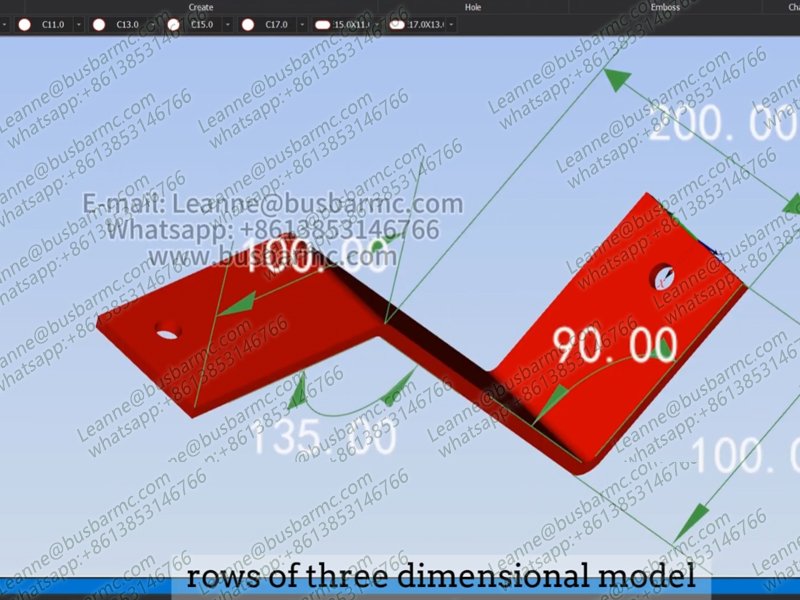

HQ400-2000B busbar bending machine adopts advanced CNC numerical control system and CAD/CAM system.

The busbar bending processing has the remarkable characteristics of high precision, high efficiency and automation.

To learn about the latest busbar bending machine prices and obtain related technical materials, contact us now.

LT Busbar Bending Machine Videos:

Infomation:

HQ400-2000B CNC busbar bending machine Specifications

| Model | HQ400-2000B |

| Nomianl Pressure | 400KN |

| Hydraulic Cylinder Stroke | 250mm |

| Main Motor Power | 5.5kw |

| Gauge Length | 2000mm |

| Gauge Accuracy | +/-0.15 |

| Bending Accuracy | +/-0.3° |

| Bending Head(Y Axis) | Fastest 5m/min; low: 1.25m/min |

| Max Moting Speed of Side striker(X Axis) | 15m/min |

| Y-axis Repeat Positioning Accuracy | +/-0.02 |

| Horizontal Bending Max.Size | 15mm x 160mm |

| Vertical Bending Max.Size | 12mm x 120mm |

| Y-axis Servo Motor Power | 5.5kw |

| X-axis Servo Motor Power | 0.75kw |

| Weight | 3300kg |

| Size | 4300mm x 1450mm x 1850mm |

Feature:

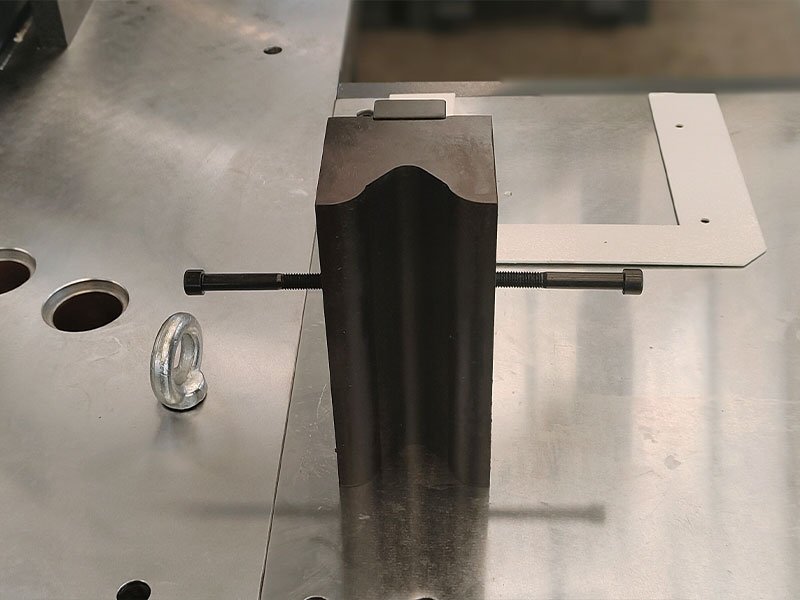

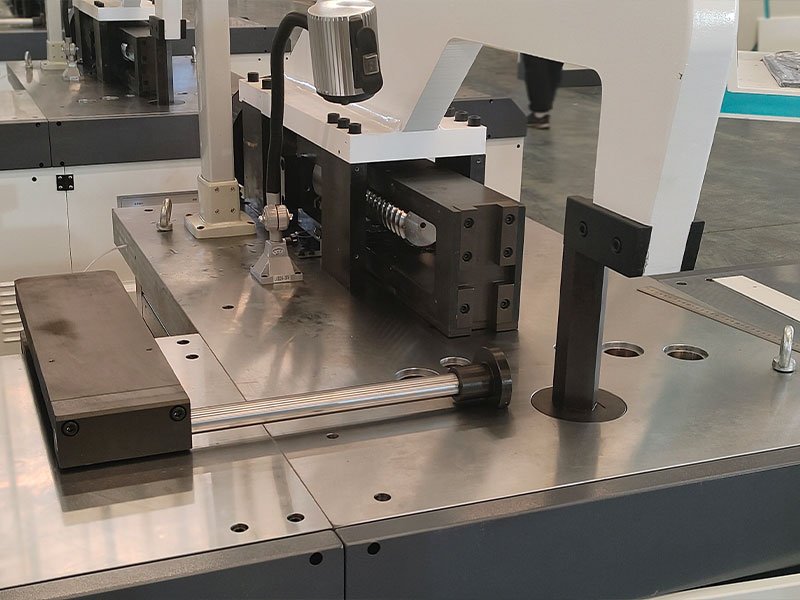

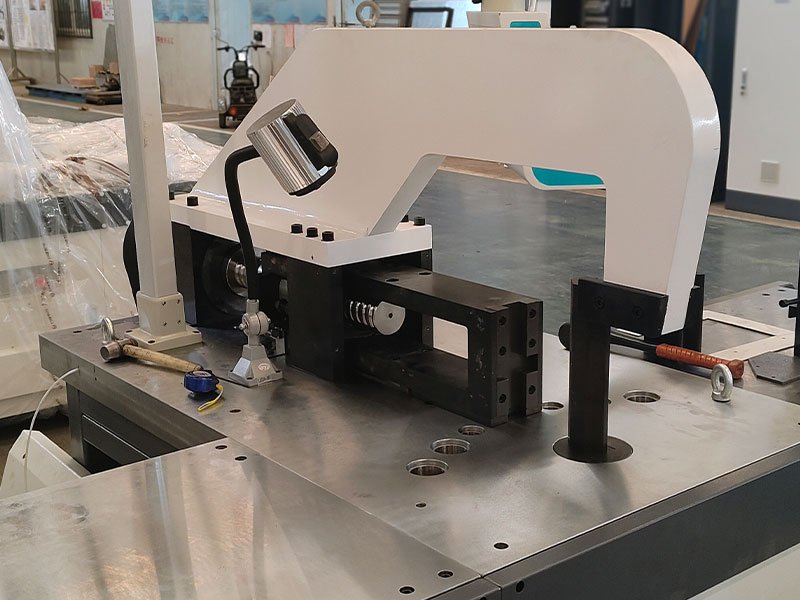

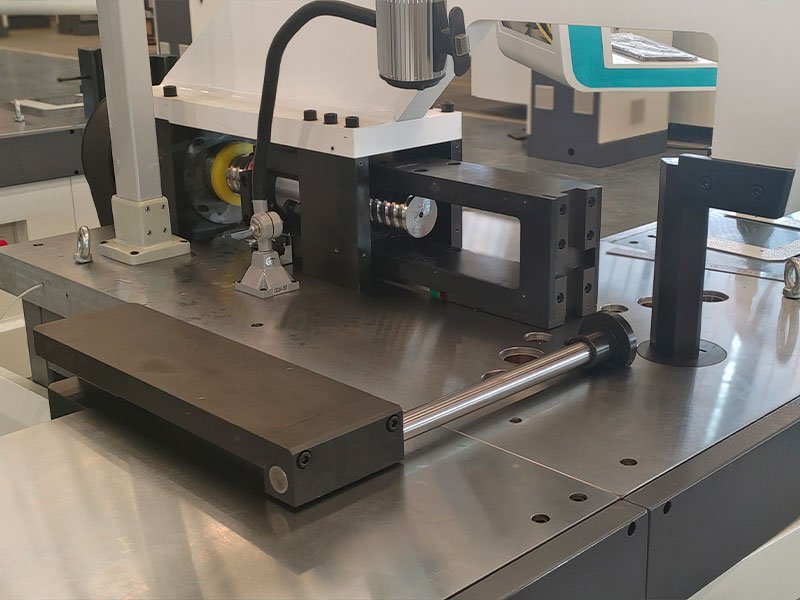

Closed bending structure .

The LT busbar bending machine structure is simple, the force is uniform, and the mechanical strength is greatly enhanced compared with open bending.

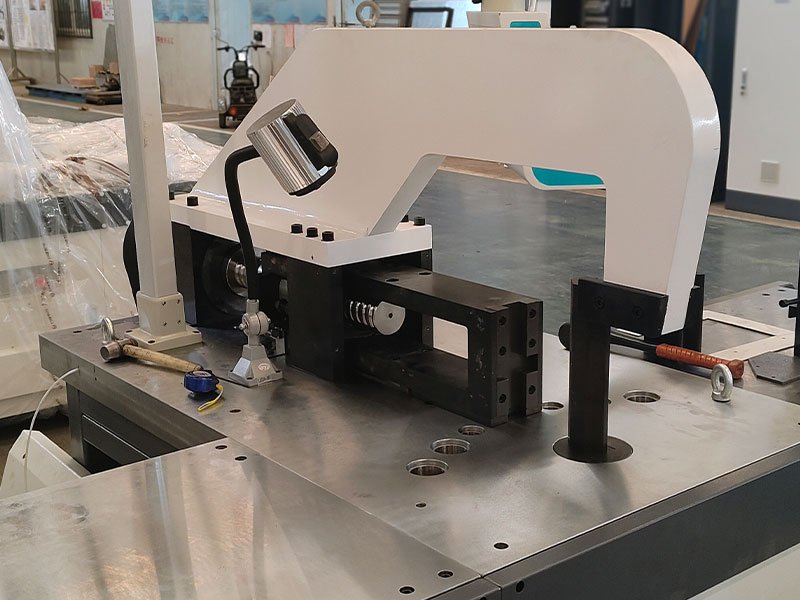

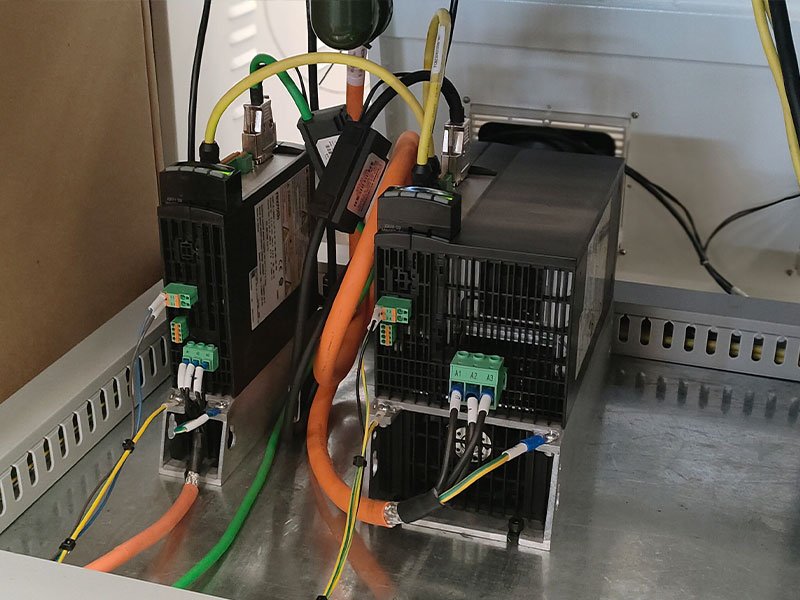

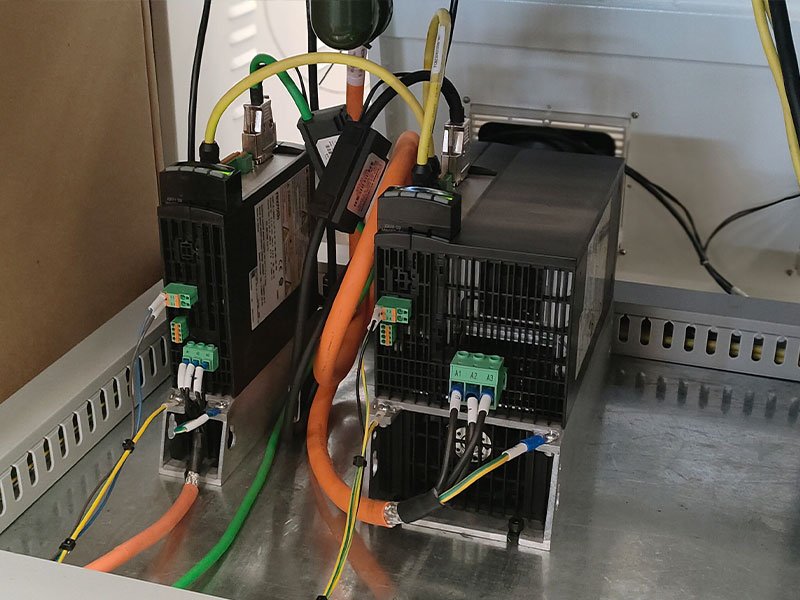

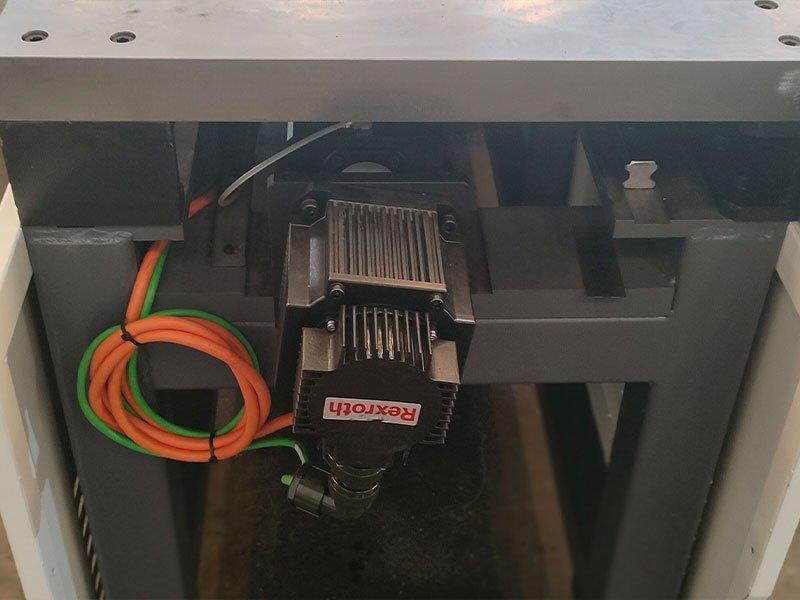

Servo motor as main power

The transmission is stable, the repeat positioning accuracy is high, the accuracy is not affected by temperature, and it is more stable.

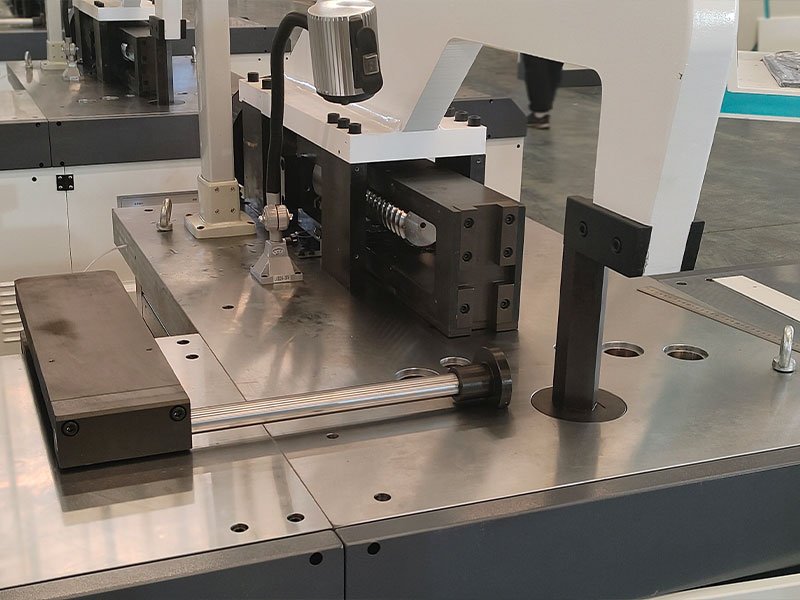

CNC stopper.

Modular design, length can be customized, smooth operation.

CNC Control Unit + CAD/CMD Software System.

CNC is the control unit, coupled with CAD/CMD software system for busbar bending machine, it is an ideal processing equipment for high and low voltage complete sets, box-type substations, transformers and other industries.

FAQ – HQ400-2000B CNC Copper Busbar Bending Machine

1. What materials can the HQ400-2000B busbar bending machine process?

This machine is suitable for bending copper and aluminum busbars within the specified size range.

2. What is the maximum bending size of the machine?

The maximum horizontal bending size is 15mm × 160mm, and the maximum vertical bending size is 12mm × 120mm.

3. What is the nominal pressure of the machine?

The HQ400-2000B has a nominal pressure of 400KN.

4. What is the gauge length and accuracy?

The gauge length is 2000mm, with a positioning accuracy of ±0.15mm.

5. What is the bending accuracy?

The bending accuracy of this model is ±0.3°.

6. What CNC and software system does the machine use?

It adopts a CNC control unit combined with CAD/CAM software for programming and bending control.

7. What are the advantages of the closed bending structure?

The closed bending structure provides uniform force distribution and higher overall mechanical strength compared with open-type bending structures.

8. What power system does the machine use?

The main power system uses a servo motor, ensuring stable transmission and high repeat positioning accuracy.

9. How fast is the bending head (Y-axis)?

The Y-axis bending head speed is 5m/min (fast) and 1.25m/min (low speed).

10. What is the maximum moving speed of the side striker (X-axis)?

The maximum X-axis moving speed is 15m/min.

11. What is the Y-axis repeat positioning accuracy?

The Y-axis repeat positioning accuracy is ±0.02.

12. How powerful are the servo motors?

The Y-axis servo motor is 5.5kW, and the X-axis servo motor is 0.75kW.

13. What industries commonly use this machine?

This machine is suitable for high and low voltage switchgear manufacturing, electrical equipment production, transformer plants, and box-type substation fabrication.

14. What is the machine size and weight?

The machine size is 4300mm × 1450mm × 1850mm, and the weight is approximately 3300kg.

15. How can I get the latest price and technical materials?

You can contact our sales or technical team to obtain updated pricing and related technical documents.

CNC copper busbar bending machine, automatic busbar bending equipment, copper aluminum busbar bending system, programmable CNC busbar bender, industrial busbar fabrication machine + Hot Tags:

CNC copper busbar bending machine, automatic busbar bending equipment, programmable CNC busbar bender, copper aluminum busbar bending system, hydraulic copper busbar bending machine, CNC busbar processing machine, CNC busbar fabrication equipment, heavy-duty busbar bending machine, precision copper bar bending machine, servo motor busbar bending system, CAD/CAM busbar bending equipment, closed-structure busbar bender, electrical switchgear busbar processing machine, copper flat bar bending equipment, transformer manufacturing busbar bender, power distribution busbar forming machine, copper bar shaping and bending machine, high-accuracy CNC busbar bending system, industrial electrical busbar bending equipment, copper busbar forming machine, aluminum busbar bending equipment, electric panel busbar bending machine, long-length busbar bending machine, CNC horizontal and vertical busbar bender, copper busbar bending workstation, professional copper bar fabrication equipment.