The LTMC-30 is a high-efficiency combined busbar processing machine designed for copper applications. It integrates bending, cutting, and punching functions into one robust system. Ideal for fabricating busbars used in switchgear and transformers. This hydraulic busbar machine ensures precision and productivity.

LTMC-30A

Product Information

Product name: Combined busbar processing machine LTMC-30A for copper

Main features: 1. It can be used at any occasion.

2. Small volume and easy to move.

3. High production capacity and high work efficiency.

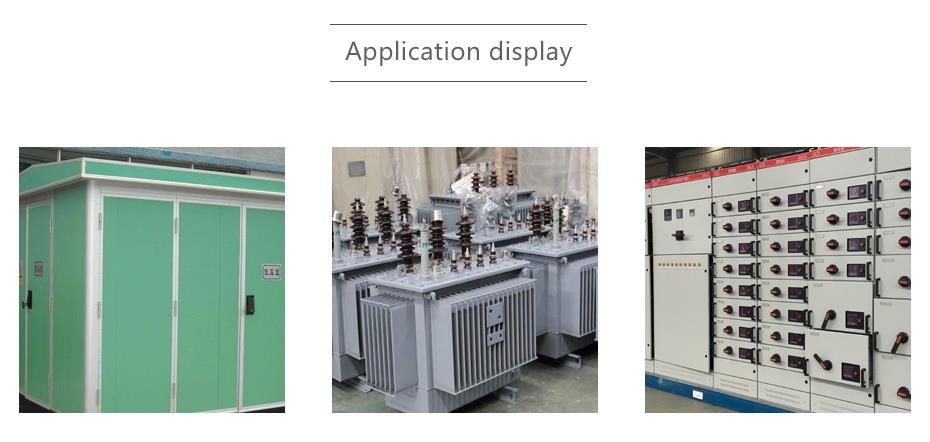

Product application: Power distribution boxes, transformer, switch canbinet.

Functions

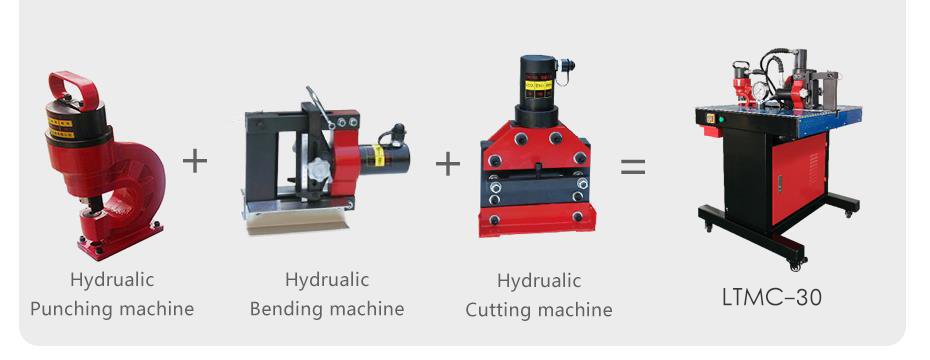

LTMC-30A has three functions : punching , cutting , bending.

It is combined with three portable busbar processing machine.

Processing Samples

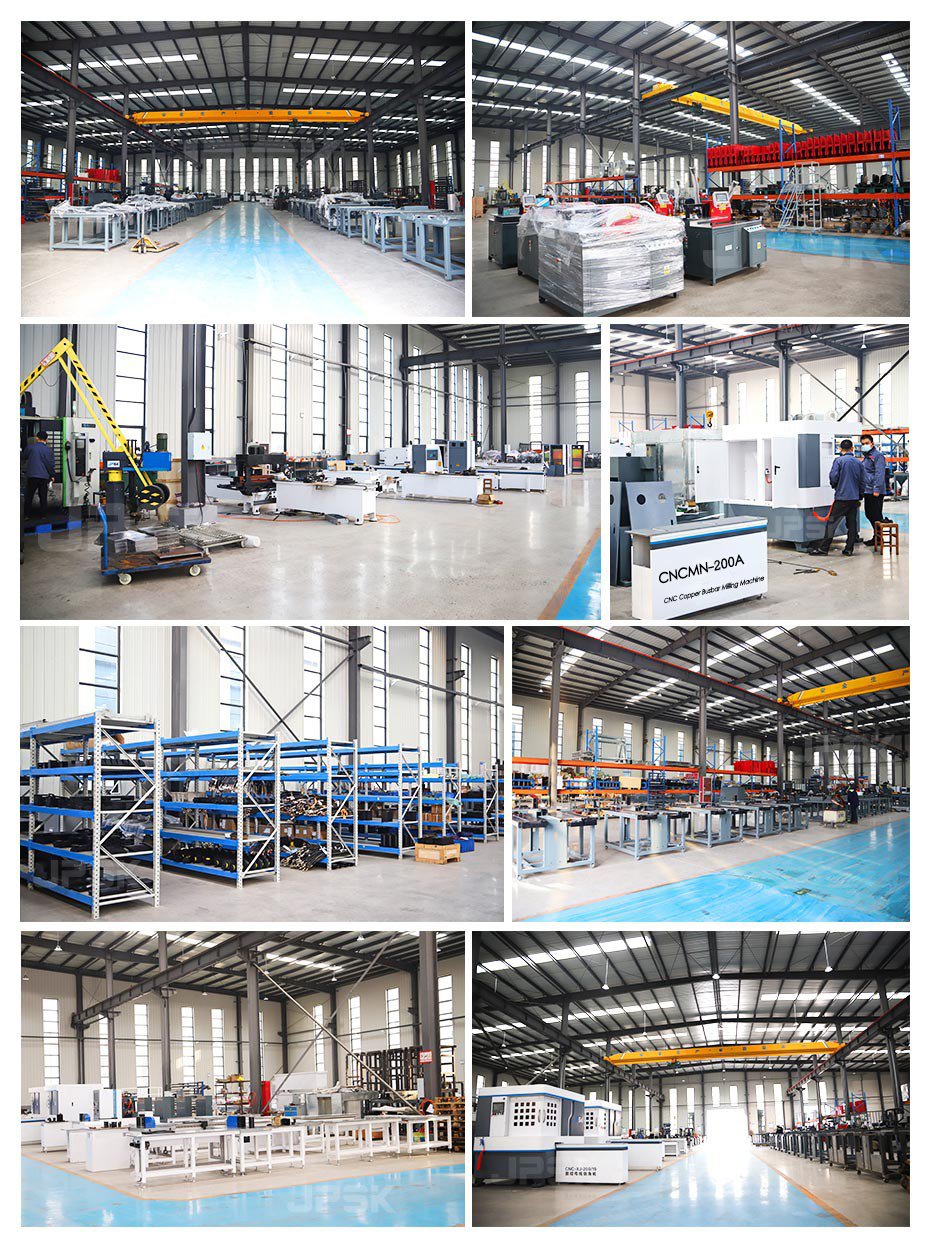

Our Factory

Business Partner

Our products sell well in Europe, North America, South America and Southeast Asia.

Our company is a partner of first-line brands such as ABB, Siemens and Schneider.

Techinical Parameters

| Item | Model |

| LTMC-30A | |

| Rated oil pressure (kn) | 630 |

| Max. processing width (mm) | 150 |

| Max. processing thickness (mm) | 10 |

| Out dimension (mm) | 690×700×1060 |

| Diameter of standard dies (mm) | ¢10.5、¢13.8、¢17、¢20.5 |

| Input voltage | 220V/50HZ |

| Container size (mm) | 760×770×1320 |

| Machine weight (kg) | 170 |

| Item | Model |

| LTMC-30B | |

| Rated oil pressure (kn) | 630 |

| Max. processing width (mm) | 200 |

| Max. processing thickness (mm) | 12 |

| Out dimension (mm) | 900×700×1160 |

| Diameter of standard dies (mm) | ¢10.5、¢13.8、¢17、¢20.5 |

| Input voltage | 220V/50HZ |

| Container size (mm) | 990×760×1320 |

| Machine weight (kg) | 205 |

Hot Tags: combined busbar processing machine LTMC-30A for copper,

Hot Tags: cnc busbar machine, 3 in1 busbar machine, busbar bending machine, busbar punching machine, busbar cutting machine, copper busbar bending machine, cnc bending machine, cnc punching machine, bending machine, busbar machine, copper busbar machine, cutter machine, machine bending, China, suppliers, manufacturers, factory, price

LTMC-30A combined busbar processing machine for copper FAQ: What is the LTMC-30A busbar machine used for? The LTMC-30A is a versatile 3-in-1 busbar processing machine designed for punching, cutting, and bending copper busbars. It is ideal for use in power distribution boxes, transformers, and switch cabinets.

What are the main features of the LTMC-30A? It is compact and portable, allowing it to be used in any location. It offers high production capacity, efficient operation, and can be easily moved due to its small size and lightweight design.

What are the technical specifications of the LTMC-30A? The machine has a rated oil pressure of 630 kN, maximum processing width of 150 mm, maximum processing thickness of 10 mm, and uses standard dies with diameters of 10.5 mm, 13.8 mm, 17 mm, and 20.5 mm. It operates on 220V/50Hz power supply, with an overall dimension of 690×700×1060 mm and weight of 170 kg.

How does the LTMC-30A perform punching, cutting, and bending? The machine is equipped with three functional units. The punching unit can make round and oblong holes. The cutting unit uses a vertical cutting mode ensuring flat, burr-free edges. The bending unit allows horizontal, vertical, flat, and U-shaped bending by changing molds.

Can the LTMC-30A be used with other molds or for custom processing? Yes, different dies or tools can be installed to achieve special shapes, embossing, flattening, twisting, or crimping as required by the user.

Is the LTMC-30A suitable for portable use? Yes, the LTMC-30A is lightweight and compact, making it easy to move to different work locations or production areas.

Where is the LTMC-30A sold and who are its main business partners? LTMC-30A machines are sold globally in Europe, North America, South America, and Southeast Asia. The company collaborates with first-line brands such as ABB, Siemens, and Schneider.

What after-sales service is provided for the LTMC-30A? The company offers full support including installation guidance, training, and regular follow-ups to ensure high performance and customer satisfaction.