The 803U-3-C is a fully-automatic 3-in-1 CNC busbar machine for precision bending, punching, and cutting of copper busbars. This hydraulic bending machine boosts efficiency in electrical component manufacturing. Get a competitive price for a high-performance solution.

CNC Copper CNC 3 in 1 Busbar Machine Product Description

This series of CNC busbar processing machine has three processing units: punching, shearing/cutting and bending. The three unit can be used simultaneously or sequentially, which shortens the processing time and improves production efficiency. The bending unit adopts Siemens PLC of Germany.

Technical Parameters

Items | Model | ||

303U-3-C | 503U-3-C | 803U-3-C | |

Nominal force (kn) | 300 | 500 | 800 |

Punching dia.range (mm) | ф4.3~ф25 | ф4.3~ф30 | ф4.3~ф34 |

Max.thickness (mm) | 12 | 16 | 20 |

Max.width (mm) | 150 | 200 | 250 |

Max.shearing thickness (mm) | 12 | 16 | 20 |

Max. shearing width (mm) | 150 | 200 | 250 |

Max.horizontal bending width (mm) | 150 | 200 | 250 |

Max.Horizontal bendind thickness (mm) | 12 | 16 | 20 |

Max.vertical bending size (mm) | 10×100 | 12×120 | 12×120 |

Power (kw) | 3×4KW | 3×5.5KW | 3×5.5KW |

Bending precision (degree) | ±1° | ±1° | ±1° |

Repeat bending precision (degree) | ±0.5° | ±0.5° | ±0.5° |

First table size (mm) | 1750×1250 | 1920×1385 | 1920×1385 |

Second table size (mm) | 985×500 | 985×500 | 985×500 |

Outside dimension (mm) | 1780×1400×1300 | 1950×1560×1390 | 1950×1560×1450 |

Container size(mm) | 1870×1480×1520 | 2060×1660×1650 | 2060×1660×1650 |

Total weight(kg) | 1400KG | 1700KG | 2100KG |

Product Details

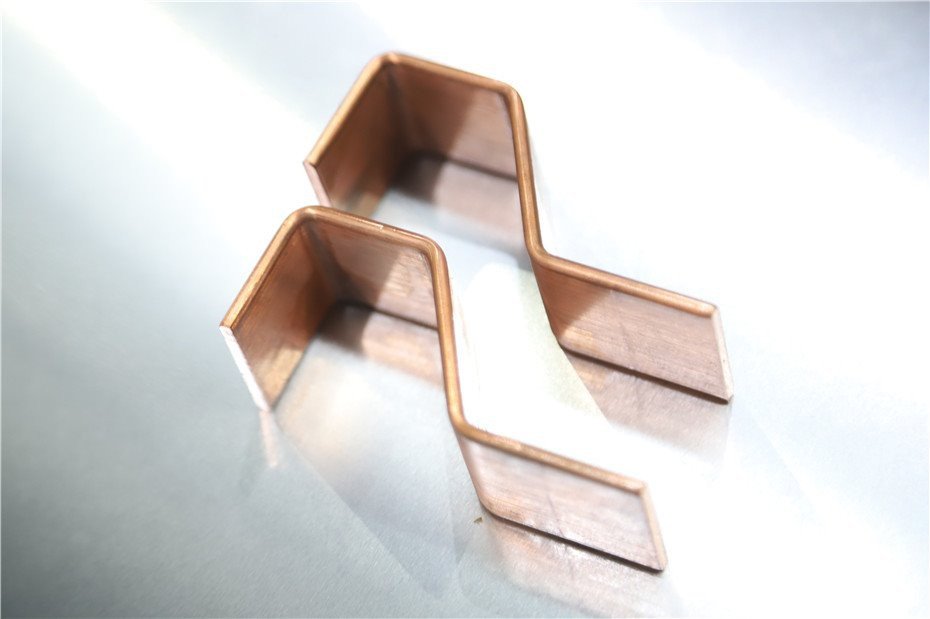

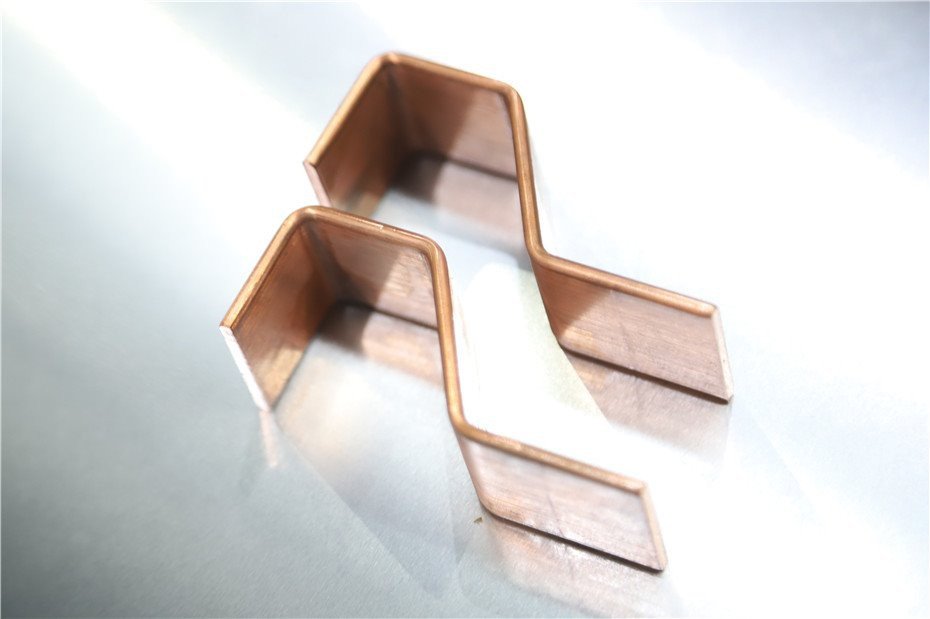

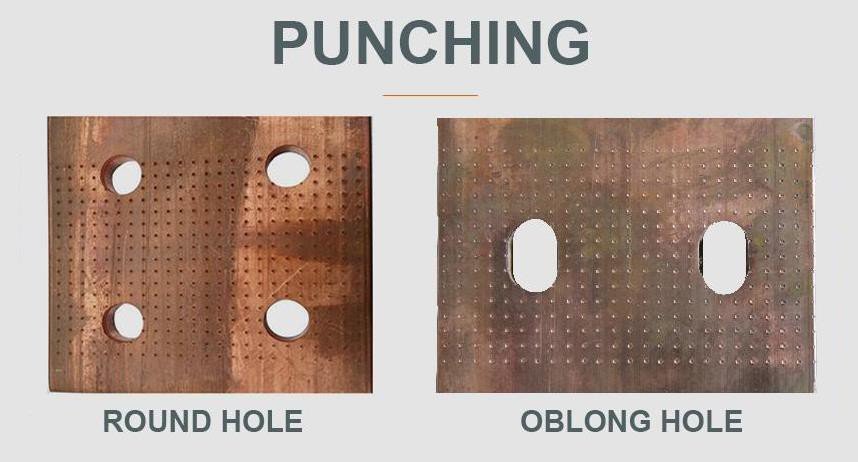

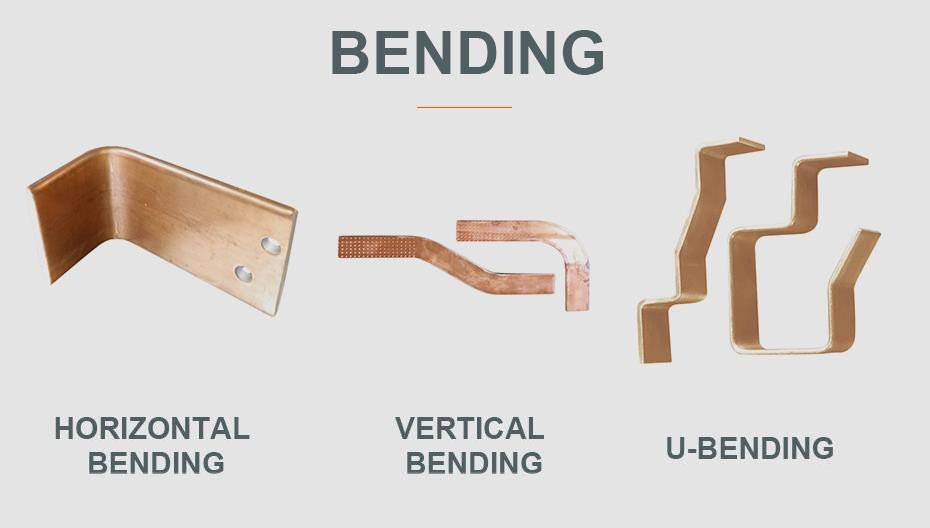

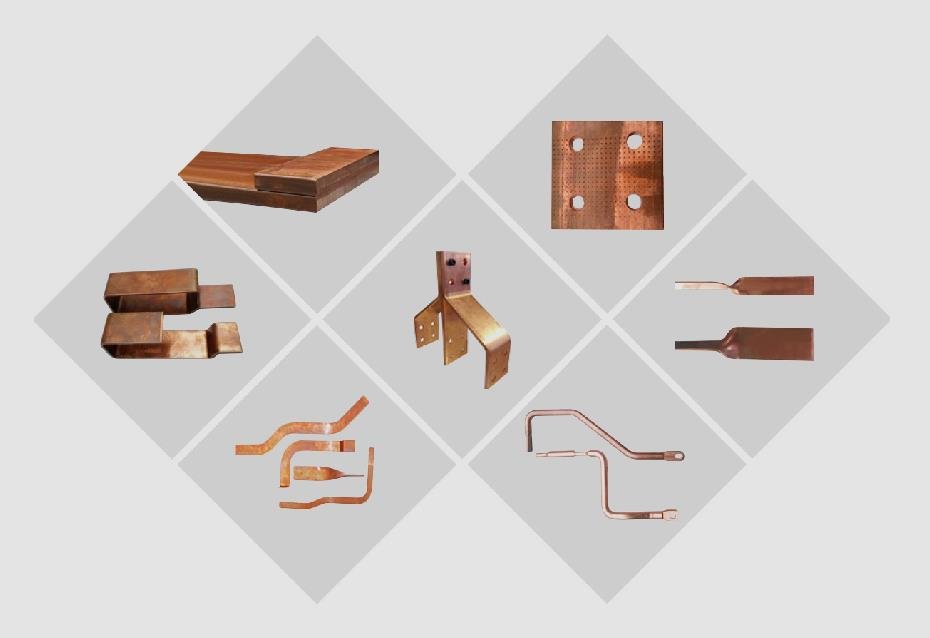

Processing Samples

The main function is processing copper and aluminum busbar in different specifications. By relative operation unit, it can do all kinds of processing to copper and aluminum busbar quickly and easily, such as shearing/cutting, punching (circular hole and oblong hole), flat/horizontal bending, vertical bending, U-bending, embossing, flat pressing, twisting, cable connector processing etc.

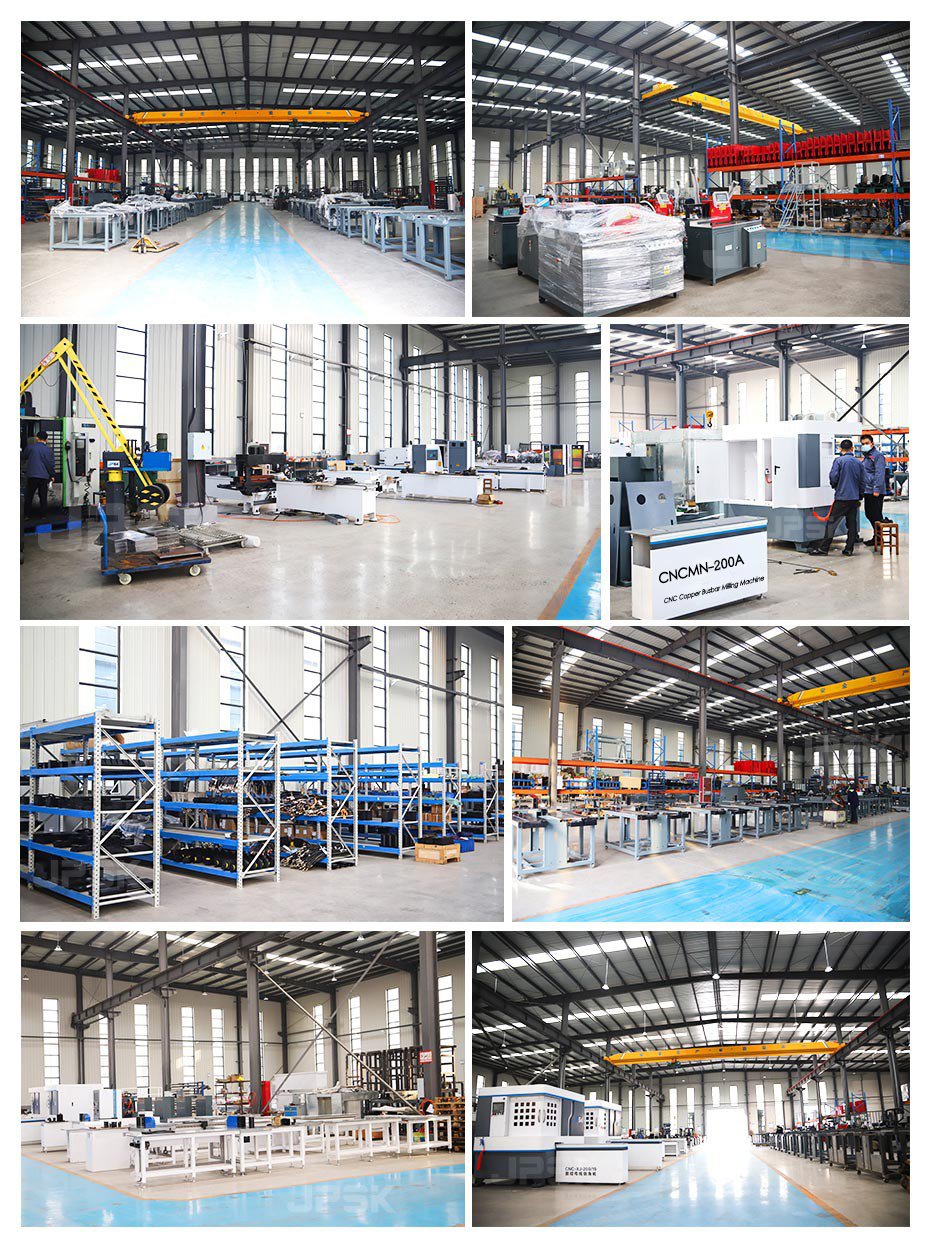

Our Factory

LTMC Company was founded in 2005. After more than 15 years of wind and rain, it has developed into a high-tech enterprise specializing in R&D, design, manufacture, sales and after-sale of electric power equipment and automation CNC equipment.

Our Service Process

1.Customer inquiry

2.Quote

3.Order

4.Release production notice

5.Ship

6.After sale

Our after-sales service engineers will also have return visit to you on a regular basis to listen to your valuable opinions and continuously improve product quality.

Package & Delivery

We use waterproof plastic film wrapped inside and wooden cases ouside.

Our Certifications

Hot Tags: cnc busbar machine, 3 in1 busbar machine, busbar bending machine, busbar punching machine, busbar cutting machine, copper busbar bending machine, cnc bending machine, cnc punching machine, bending machine, busbar machine, copper busbar machine, cutter machine, machine bending, China, suppliers, manufacturers, factory, price

LT Busbar Machine Videos:

803U-3-C 3 in 1 Busbar Machine FAQ

Q1: What is the 803U-3-C 3 in 1 Busbar Machine used for?

A1: The 803U-3-C is a CNC busbar processing machine that integrates punching, shearing/cutting, and bending units. It efficiently processes copper and aluminum busbars and can perform operations such as punching, flat/horizontal bending, vertical bending, U-bending, embossing, flat pressing, twisting, and cable connector processing.

Q2: Can the 803U-3-C perform multiple operations at the same time?

A2: Yes, its three units can be used simultaneously or sequentially, which helps improve production efficiency and save processing time.

Q3: What kind of control system does the machine use?

A3: The bending unit is controlled by a Siemens PLC system, ensuring precise and reliable operation.

Q4: What materials can the 803U-3-C process?

A4: It is suitable for processing copper and aluminum busbars of various specifications.

Q5: How is the machine packaged for delivery?

A5: The machine is wrapped in waterproof plastic film inside and wooden cases outside to ensure safe transportation.

Q6: Does the manufacturer provide after-sales service?

A6: Yes, LTMC offers complete after-sales service, including regular follow-up visits from service engineers to ensure customer satisfaction and continuously improve product quality.

Q7: Who manufactures the 803U-3-C machine?

A7: The 803U-3-C is manufactured by LTMC, a Chinese high-tech company specializing in R&D, design, manufacturing, sales, and after-sales of electric power and CNC automation equipment since 2005.