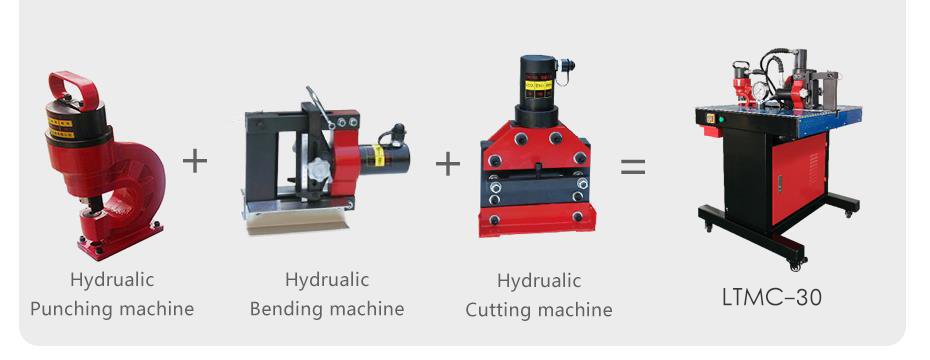

The LTMC-30 is a high-performance hydraulic 3-in-1 busbar processing machine designed for bending, punching, and cutting copper busbars. With a maximum processing width of 150mm and thickness of 10mm, this versatile busbar machine is ideal for electrical manufacturing applications including switchgear and transformer production.

LTMC-30

Product Information

Product Image

Product Introduction

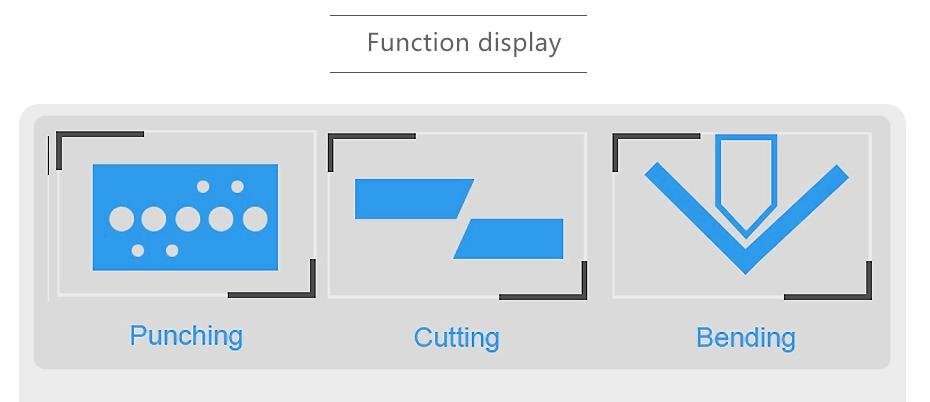

LTMC-30A has three processing units: punching, shearing/cutting and bending. And it's mainly used for processing copper and aluminum busbar in differernt specifications.

Product Processing Samples

PUNCHING / CUTTING / BENDING

The max. processing width is 150mm.

The max. processing thickness is 10mm.

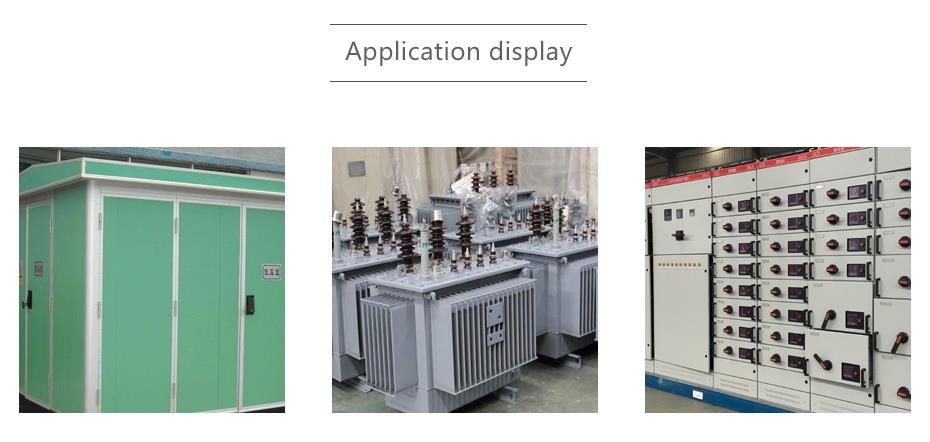

Product Application

The machine uses a single-phase 220v ordinary power supply, which can be used in any occasion, such as on-site construction of large workshops, transmission, distribution work, electrical manufacturing plants such as power distribution cabinets and switch canbinets.

High and low voltage switchgear, substation, busway, bridge, electrical switch, communication equipment, household appliances, shipbuilding, office automation equipment, elevator manufacturing, chassis manufacturing and other electrical equipment manufacturing industry. Most suitable for making large electric control box and transmission and distribution construction project construction site use.

Single Processing unit

Company Advantages

Our Factory

We have professional engineers to serve you form the beginning to the end.

We can guarantee the product quality and service quality.

Our Certifications

Our Business Partner

Such ABB, Siemens, Schneider and EDK.

Our Visitors

Our products are sold in more than 100 countries all around the world.

Including the United States, Britain, Germany, Russia, Canada, Belgium, Argentina, New Zealand, Czech Republic, Romania, Ireland, Peru, Chile, Australia, Hungary, Mexico, Slovenia, Malaysia, Brazil, Vietnam, Saudi Arabia, Pakistan, etc.

Due to its superior product performance, powerful functions, stable quality, and timely after-sales service, it has won unanimous praise from customers, also has achieved long-term cooperation and has always maintained friendly contacts.

| Item | Model |

| LTMC-30 | |

| Rated oil pressure (kn) | 630 |

| Max. processing width (mm) | 150 |

| Max. processing thickness (mm) | 10 |

| Out dimension (mm) | 700×700×1100 |

| Diameter of standard dies (mm) | ¢10.5、¢13.8、¢17、¢20.5 |

| Input voltage | 220V/50HZ |

| Container size (mm) | 990×760×1320 |

| Machine weight (kg) | 165 |

Hot Tags: three portable busbar processing machines combined LTMC-30A copper busbar processing,

Hot Tags: cnc busbar machine, 3 in1 busbar machine, busbar bending machine, busbar punching machine, busbar cutting machine, copper busbar bending machine, cnc bending machine, cnc punching machine, bending machine, busbar machine, copper busbar machine, cutter machine, machine bending, China, suppliers, manufacturers, factory, price

LTMC-30A 3 in 1 portable busbar processing machine FAQ: What is the LTMC-30A busbar machine used for? The LTMC-30A integrates punching, shearing/cutting, and bending functions, primarily used for processing copper and aluminum busbars of various specifications.

What is the maximum processing width and thickness? The LTMC-30A can handle busbars up to 150mm wide and 10mm thick, making it suitable for a variety of industrial applications.

What type of power supply does the machine require? This machine uses a single-phase 220V/50HZ power supply, which allows it to be used on-site at construction sites, workshops, and electrical manufacturing facilities.

What industries can benefit from the LTMC-30A? It is ideal for electrical switchgear, substations, busways, high and low voltage panels, power distribution cabinets, communication equipment, household appliances, shipbuilding, office automation, elevator and chassis manufacturing, and other electrical equipment production.

How portable is the LTMC-30A machine? The LTMC-30A is designed as a compact, portable machine with an overall dimension of 700×700×1100mm and a weight of 165kg, making it suitable for both factory and on-site applications.

Does the LTMC-30A offer standardized punching dies? Yes, it comes with standard die diameters of ¢10.5, ¢13.8, ¢17, and ¢20.5, providing flexibility for different processing needs.

What kind of support and service is provided? Our professional engineers provide complete support from installation to operation guidance, and after-sales service ensures long-term reliability and customer satisfaction.

Which major companies use LTMC busbar machines? Our machines have been supplied to renowned companies like ABB, Siemens, Schneider, and EDK, and are used in over 100 countries worldwide, including the USA, Germany, UK, Russia, Canada, Australia, Brazil, Vietnam, and more.

cnc busbar machine, 3 in1 busbar machine, busbar bending machine Hot Tags:

busbar punching machine, busbar cutting machine, copper busbar bending machine, cnc bending machine, cnc punching machine, bending machine, busbar machine, copper busbar machine, cutter machine, machine bending, portable busbar processing machine, LTMC-30A, hydraulic busbar machine, copper busbar machine suppliers, industrial busbar machine, busbar fabrication equipment, compact busbar machine, electric control box processing, switchgear busbar machine, busway processing machine, electrical panel manufacturing, busbar production machine, workshop busbar equipment, small busbar machine, professional busbar machine, custom busbar machine, China busbar machine factory, busbar machine price, busbar machine manufacturer