LTMC HQ600-S-8P CNC busbar punching machine is a high-performance CNC busbar processing machine that integrates punching and shearing.

HQ600-S-8P CNC busbar punching machine

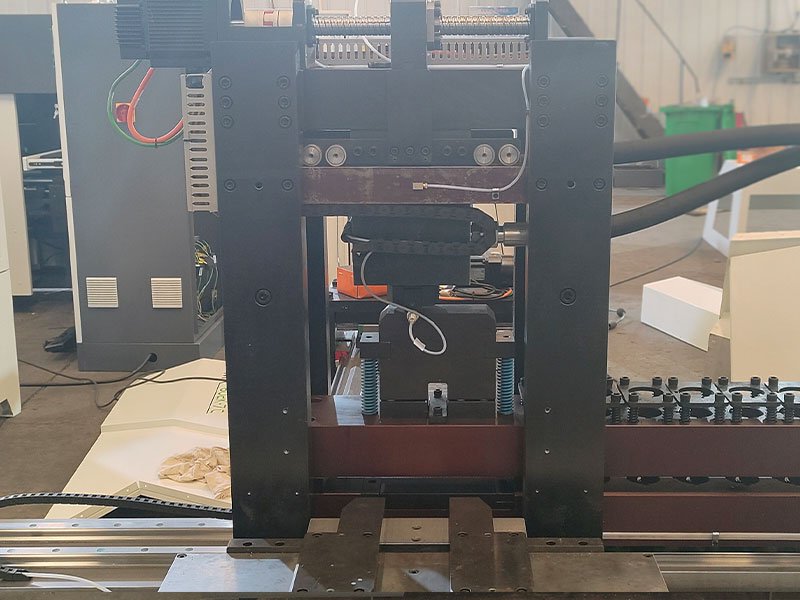

LTMC HQ600-S-8P CNC busbar punching machine is a high-performance CNC busbar processing machine that integrates punching and shearing. The HQ600-S-8P CNC busbar punching and shearing machine adopts a straight column mold frame with 8 punching,1 shearing to ensure the concentricity of the upper and lower dies during long-term use during processing. It is also equipped with CNC control system and CAD/CAM system, which greatly improves the production efficiency of busbar punching and shearing. Get the latest busbar punching and shearing machine prices, contact us now.

LT Busbar Machine Videos:

Infomation:

HQ600-S-8P CNC Copper busbar punching machine Specifications

| Model | HQ600-S-8P |

| Maximum Force | 600KN |

| Feeding Station Size | 3000x500mm |

| Discharge Station Size | 2500x500mm |

| Maximum Plate Size | 6000x200x15mm |

| Maximum Processing Thickness | 15mm |

| Maximum Processing Width | 200mm |

| Maximum Punching Diameter | Ø4.3-Ø55mm |

| Maximum Number of Cutting Dies | 1 |

| Maximum Number of Punching Dies | 8 |

| X-Axis Maximum Travel | 2000mm |

| X-Axis Accuracy Error | 0.10/500mm |

| Y-Axis Maximum Travel | 960mm |

| Y-Axis Accuracy Error | 0.10/500mm |

| Z-Axis Maximum Travel | 310mm |

| X-Axis Maximum Positioning Speed | 75m/min |

| Striking Cylinder Stroke | 45mm |

| Number of Control Axes | 6 |

| Dimensions (LxWxH) | 10500x2750x1800mm |

| Weight | 6700kg |

Feature:

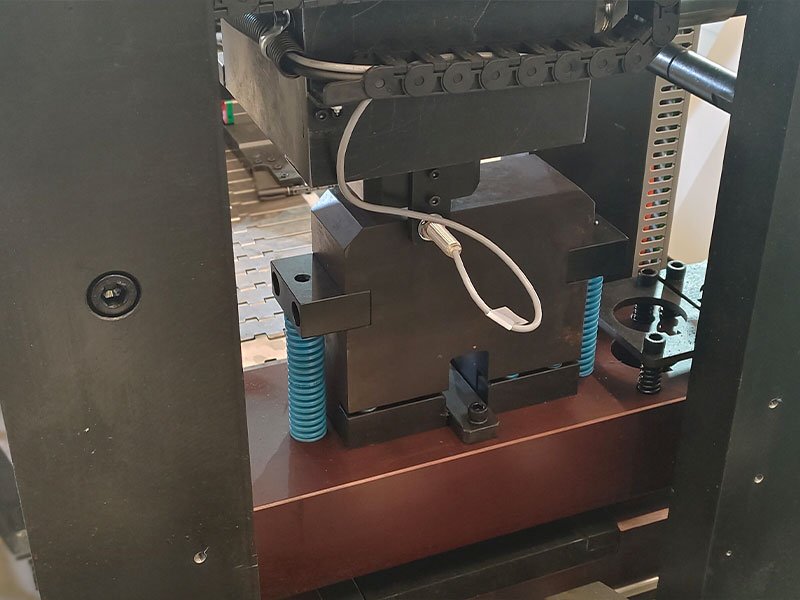

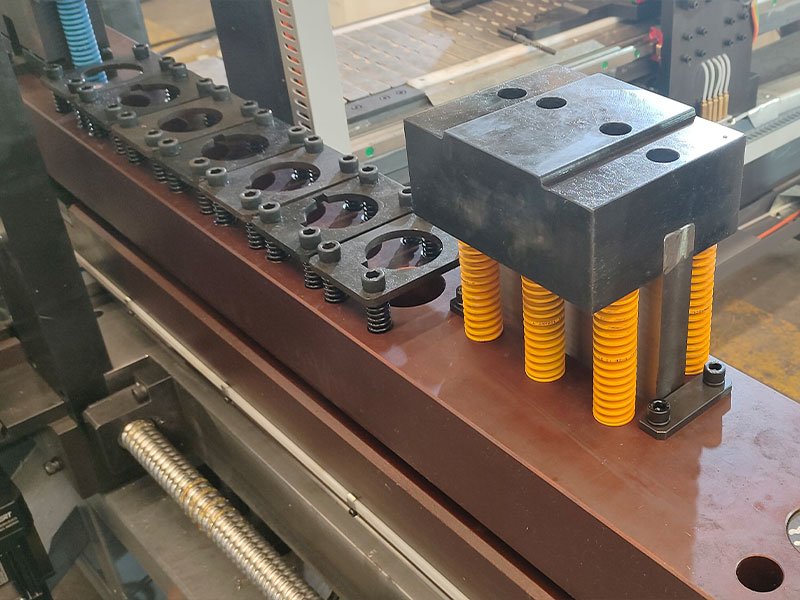

Straight column single row die library, consisting of 8 punching mold + 1 shearing mold .

Single-row die library design, with 8 punching mold + 1 shearing mold in the same row to ensure the concentricity of the punching and shearing work. While ensuring the punching and shearing efficiency (40m/min), the precision control can reach 0.1mm/500mm.

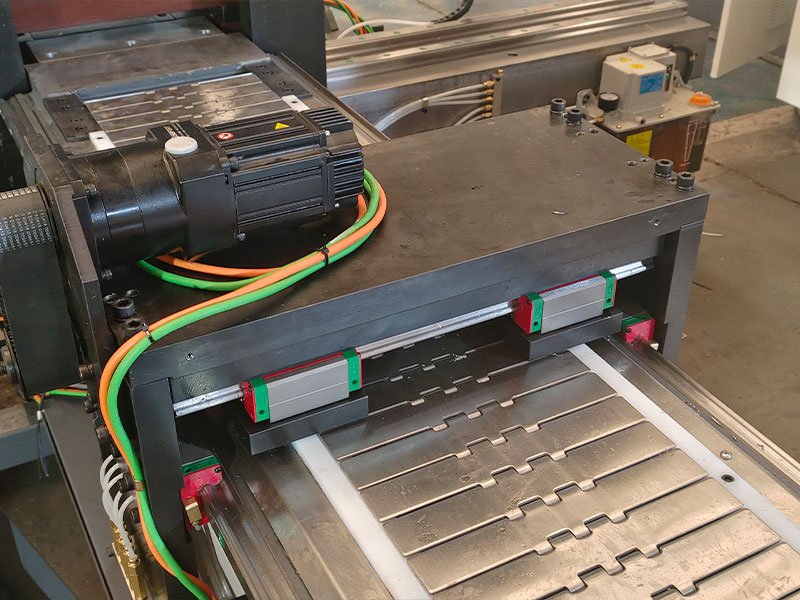

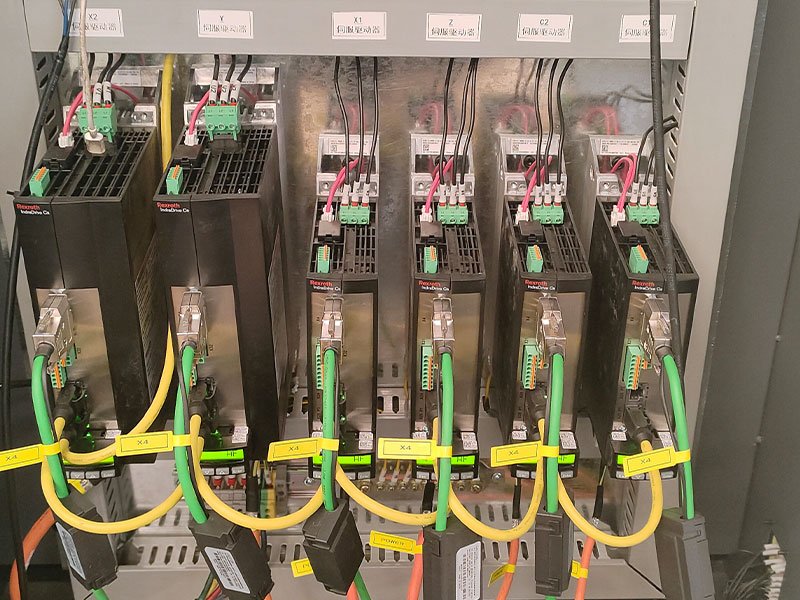

servo system is used to achieve 6-axis control, and the X-axis punching and shearing efficiency is Max 75m/min

6-axis motion system adopts 6 servo servers and 6 servo motors to drive control, with high control accuracy. Among them, the effective stroke

of the X1 servo clamp is 110mm, and the effective stroke of the X2 servo clamp is 2000mm. The X-axis motion efficiency is improved by

shortening the feed stroke and lengthening the discharge stroke. Max 75m/min (150m/min under no-load condition) in the punching

and shearing working state.

Equipped With A Swiss ABB Motor, It Supplies 600KN Hydraulic Pressure.The hydraulic station uses

Swiss ABB motor to provide 600KN hydraulic pressure, all of which is supplied to the punching and shearing unit,

effectively ensuring sufficient hydraulic pressure and punching and shearing work stability.

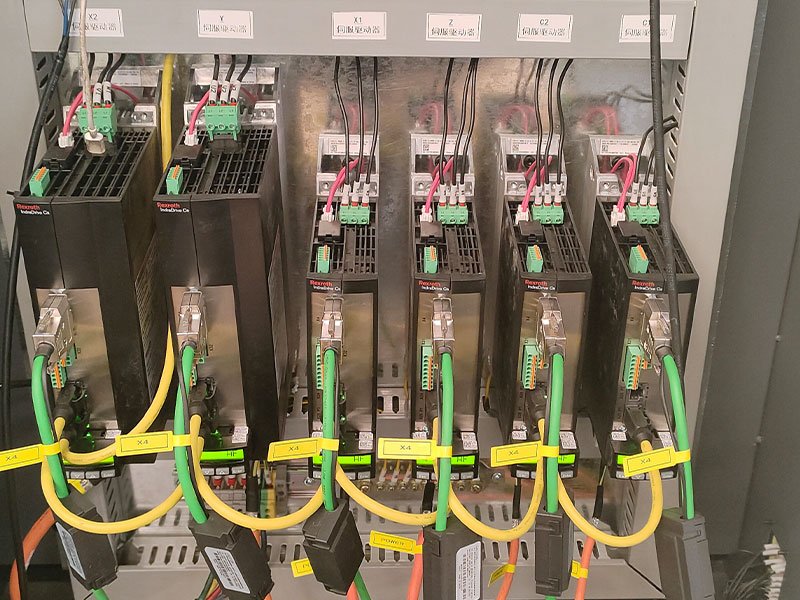

German Beckhoff System, German Rexroth Servo Motor And Servo Server.

German Beckhoff control system has closed-loop control, which has the advantages of high control accuracy,

strong anti-interference ability and flexible self-adaptation.

(Siemens control system has poor precision control, adopts open-loop control,

and is prone to data loss.) The equipment uses internationally renowned brand

accessories (German Rexroth), which are more stable than Chinese self-developed

brands and have lower maintenance costs.