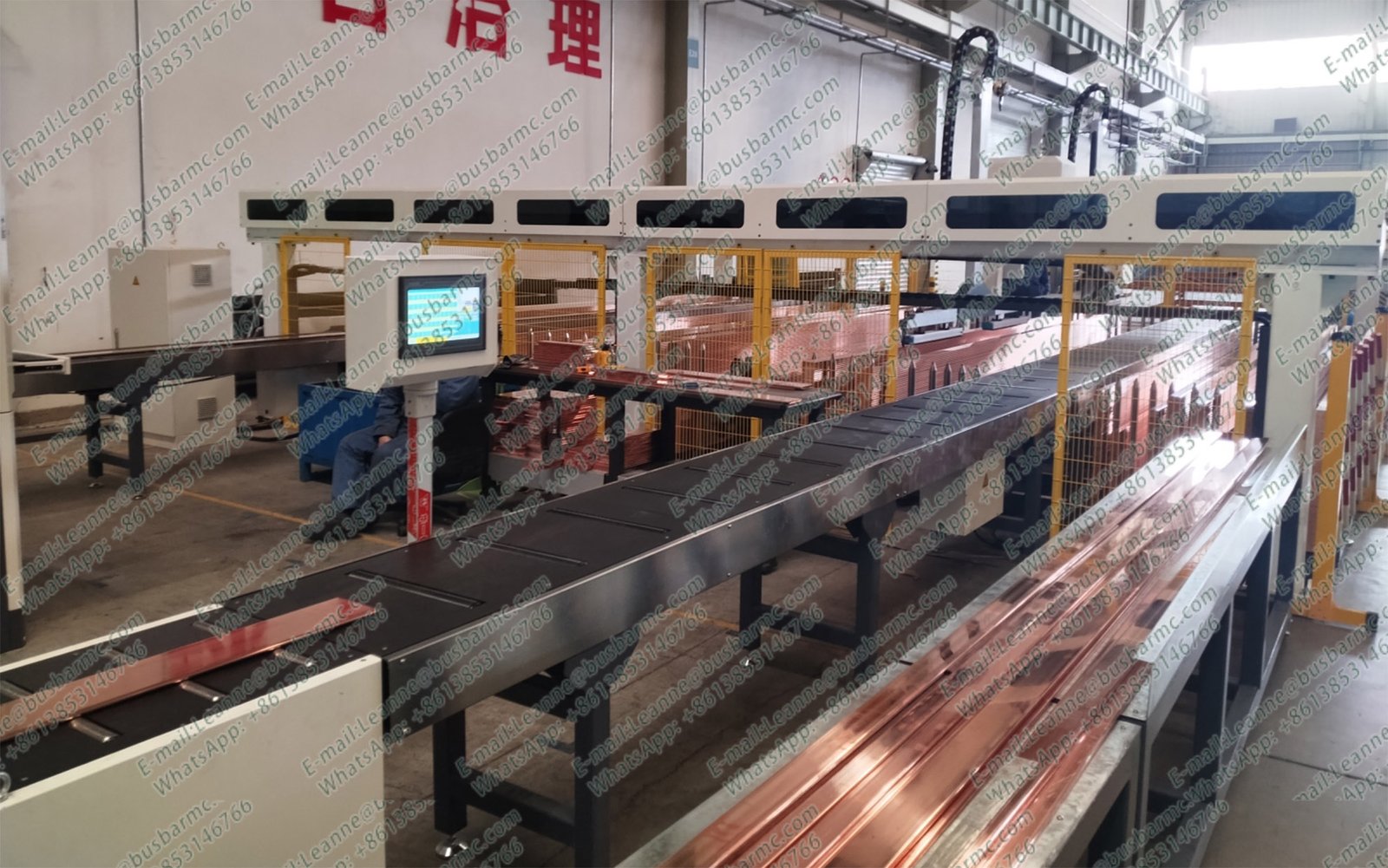

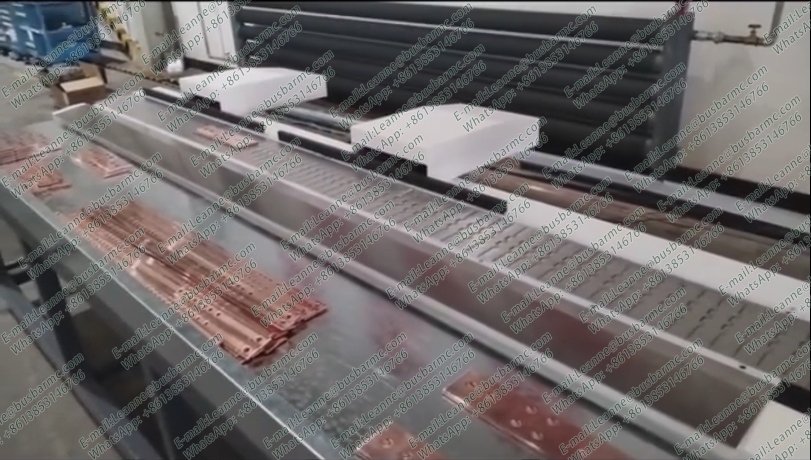

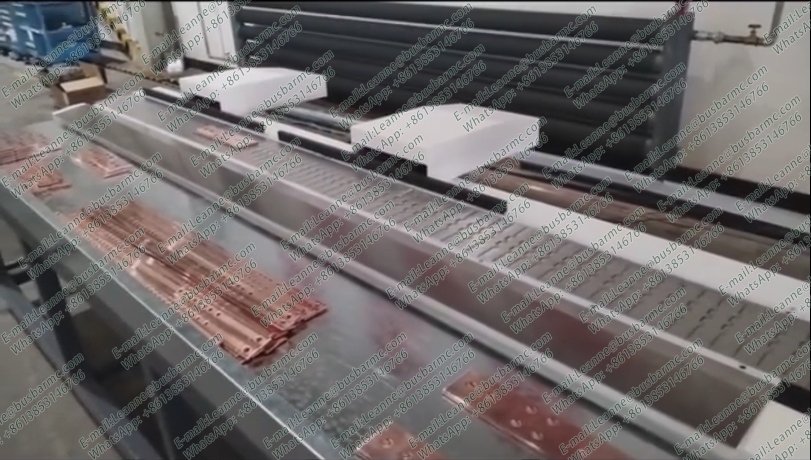

Revolutionize your busbar processing line with the CNCLK40. Designed for seamless integration with CNC punching, shearing, and bending machines, this automatic loading unit eliminates manual heavy lifting. It ensures precise material feeding, protects copper surfaces from scratches, and significantly boosts production efficiency. The ideal solution for high-volume switchgear and electrical cabinet manufacturing.

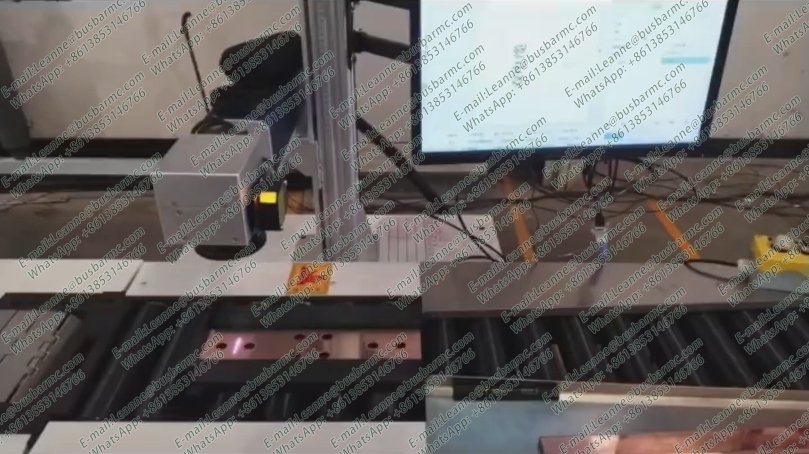

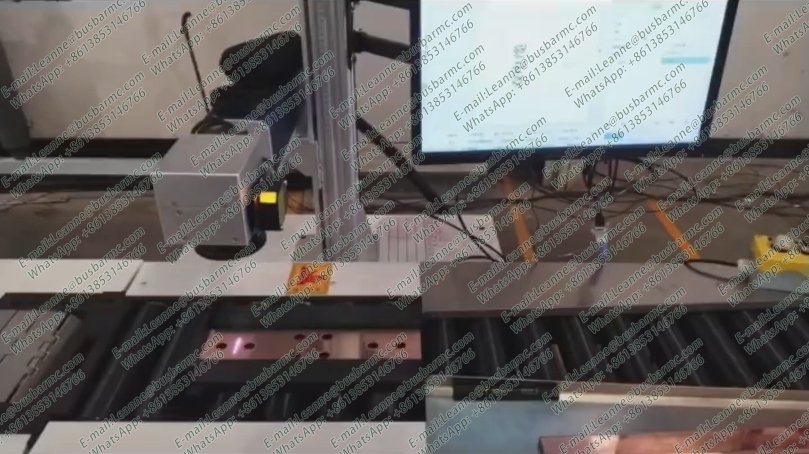

Automatic CNC Copper Busbar Loading Machine CNCLK40

The automatic feeding equipment for bus bars, integrated with our self-developed HQ600 series busbar punching and

shearing machines, enables automated copper busbar processing. Its advantages lie in enhancing the level of automation,

reducing labor intensity, minimizing waste caused by manual feeding errors, and improving production efficiency.

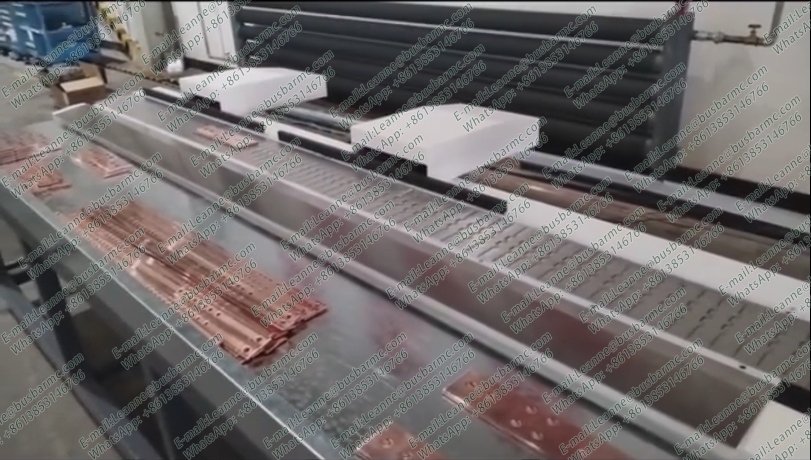

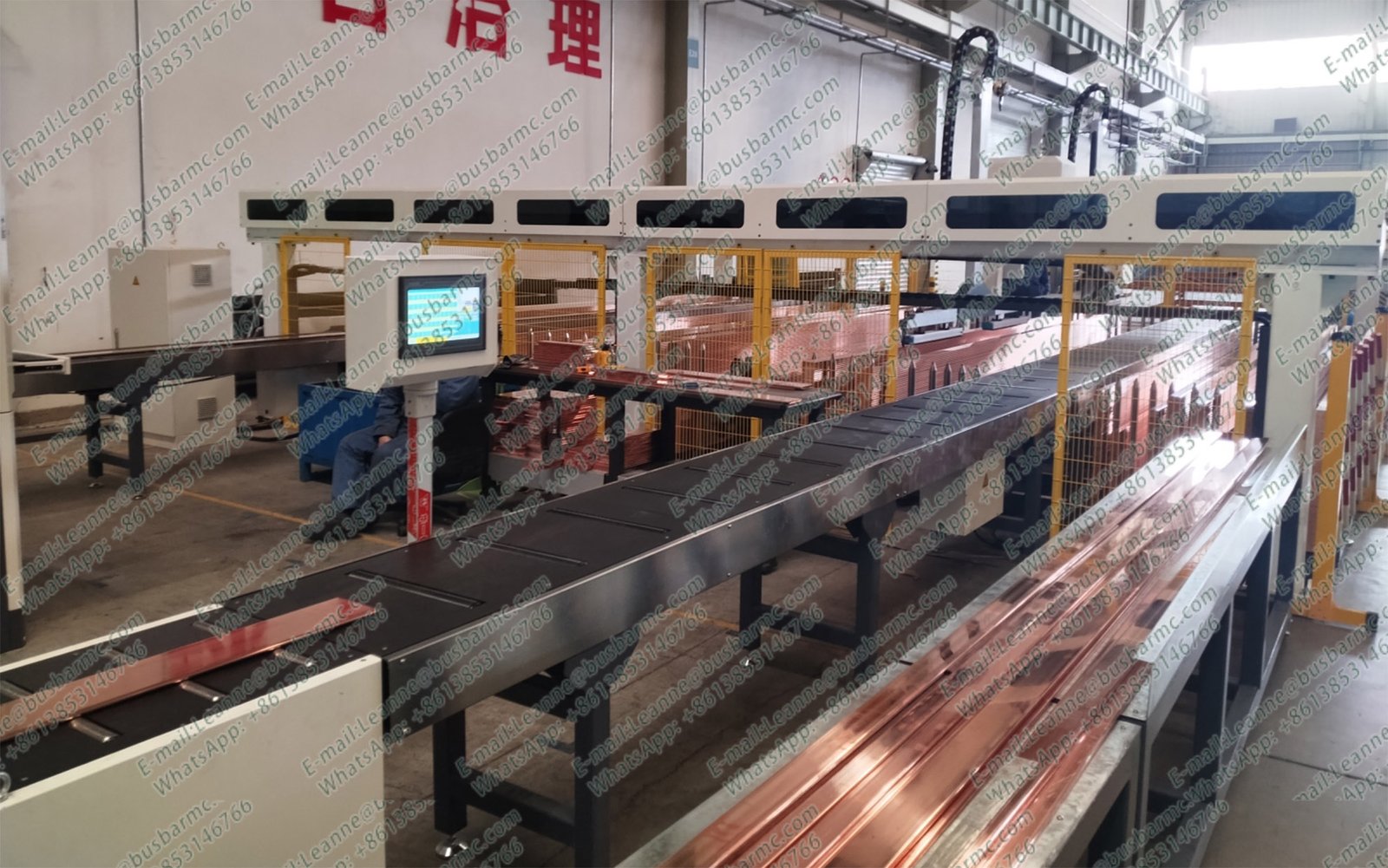

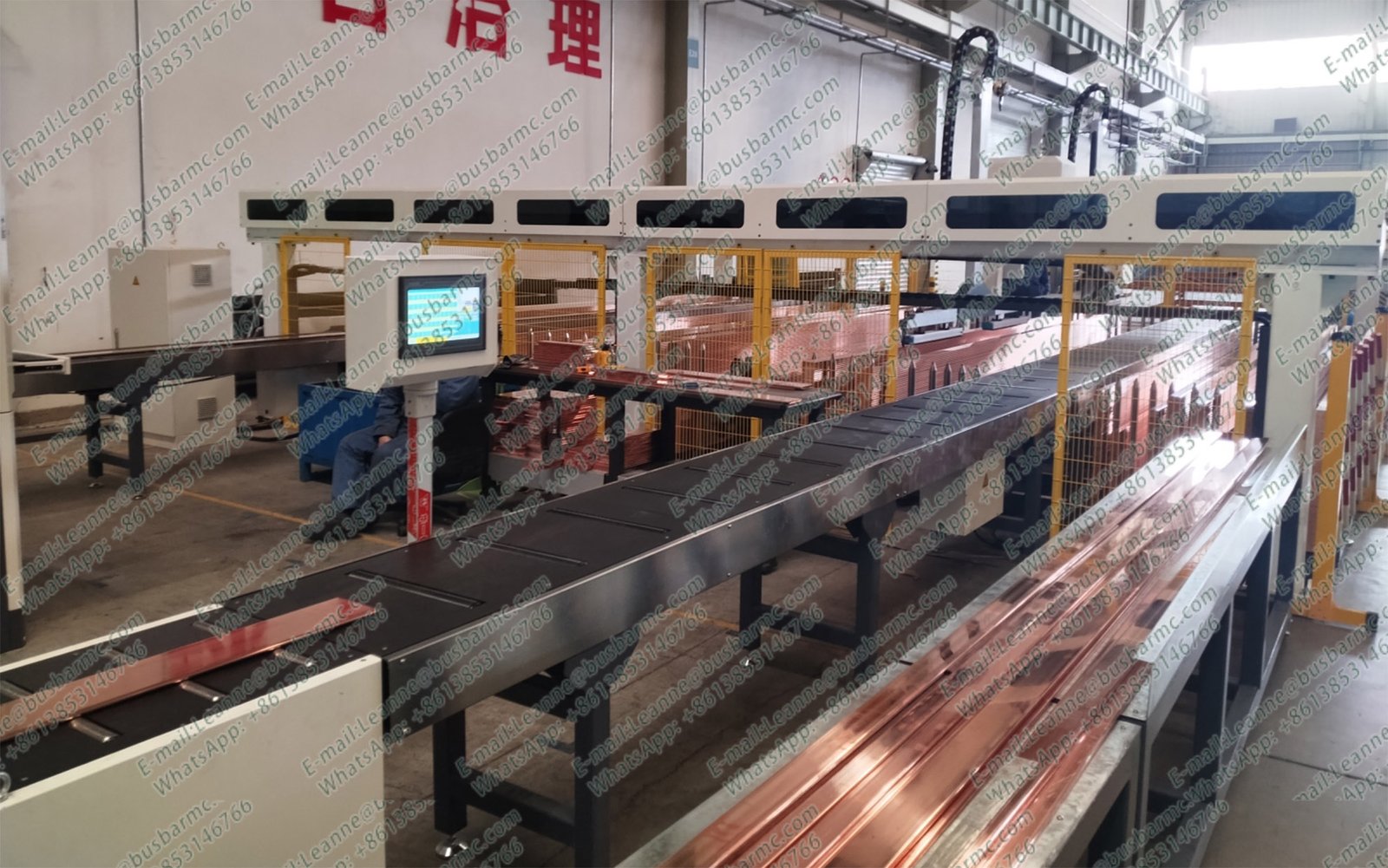

• The facility includes a sorting and unpacking area, manual stacking area, inventory storage, and a feeding zone

for punching and shearing, all arranged in an efficient layout.

• Reserved areas for bending and arc smiling processes are included.

• The overall layout is square, rational, and space efficient.

* Compatible with HQ400/HQ600 series punching machines

* Standard processing width: 30-160mm (customizable)

CNCLK40 Automatic CNC Copper Busbar Loading Machine FAQ:

Q1: What is the main function of the CNCLK40 model in automatic CNC copper busbar loading?

A1: The CNCLK40 is an automatic feeding machine designed to integrate with HQ600 series busbar punching and shearing machines. It automates copper busbar processing, reducing labor intensity, minimizing manual feeding errors, and improving production efficiency.

Q2: What are the key features of the CNCLK40 busbar loading machine?

A2: Key features include:

1. Includes sorting and unpacking area, manual stacking area, inventory storage, and feeding zone for punching and shearing.

2. Reserved zones for bending and arc smiling processes.

3. Square, rational, and space-efficient layout for optimized workflow.

Q3: What copper busbar widths and storage options does the CNCLK40 support?

A3: The machine supports copper busbar widths from 30mm to 125mm with corresponding storage compartments ranging from 6 to 42, providing flexible storage for efficient production.

Q4: Which machines is the CNCLK40 compatible with?

A4: CNCLK40 is compatible with HQ400 and HQ600 series punching and shearing machines, enabling seamless integration into existing busbar processing lines.

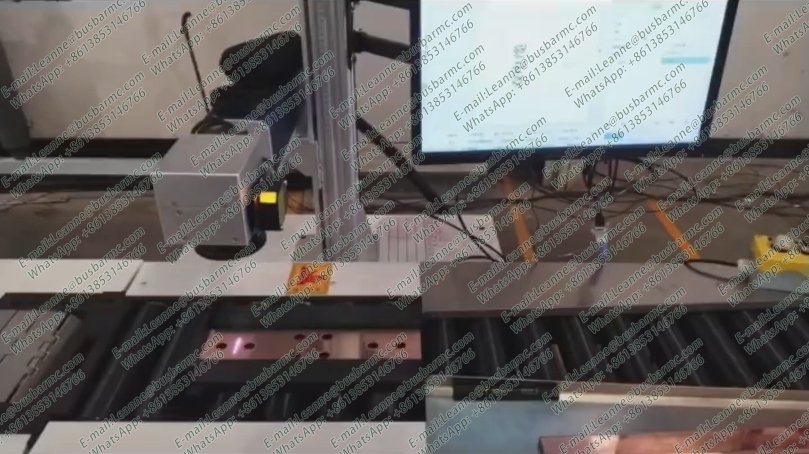

Q5: What accessories are included with the CNCLK40 automatic loading machine?

A5: Accessories include:

1. Beckhoff Controller (1 set)

2. Rexroth Servo Motors (2 sets)

3. Airtac Pneumatic Components (1 set)

4. Rexroth Ball Screw (1 set)

5. Shangyin Taiwan Linear Guide (1 set)

6. Siemens Low Voltage Electrical Appliance (1 set)

7. Qi Yang Display (1 set)

Automatic CNC Copper Busbar Loading Machine, CNCLK40, busbar feeding system, CNC busbar automation Hot Tags: automatic copper busbar loader, CNC busbar loading machine, CNCLK40 busbar feeder, copper busbar automation system, busbar punching integration, busbar shearing machine feeder, HQ600 series compatibility, busbar production efficiency, automated busbar processing, copper busbar storage solution, busbar bending preparation, arc smiling process busbar, industrial busbar automation, high efficiency busbar machine, CNC busbar material handling, flexible busbar storage compartments, automated copper busbar line, busbar production workflow optimization, compact busbar loading system, intelligent busbar handling machine