The 303U-3-C is a high-quality 3-in-1 CNC busbar fabrication machine designed for precision bending, punching, and cutting of copper/aluminum busbars. With hydraulic operation and 0.3 repeat bending accuracy, it is ideal for electrical component manufacturing. This durable machine supports max 12mm thickness and 160mm width processing, ensuring efficiency for switchgear and transformer production.

Best Quality Copper/Aluminum Busbar Fabrication Machine

Product Description:

This series three in one Best Quality Copper/Aluminum Busbar Fabrication Machine has three units: punching, shearing and bending.It is easy to adjust each unit to shorten the processing time and improve the production efficiency.

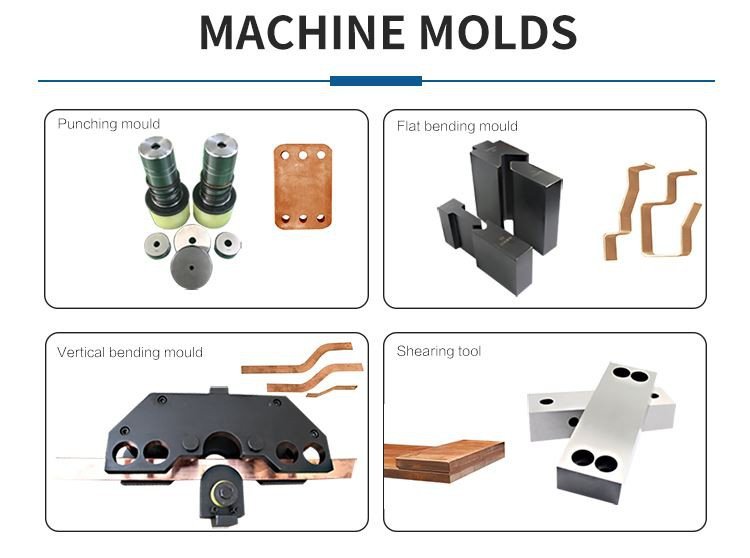

Detailed Images:

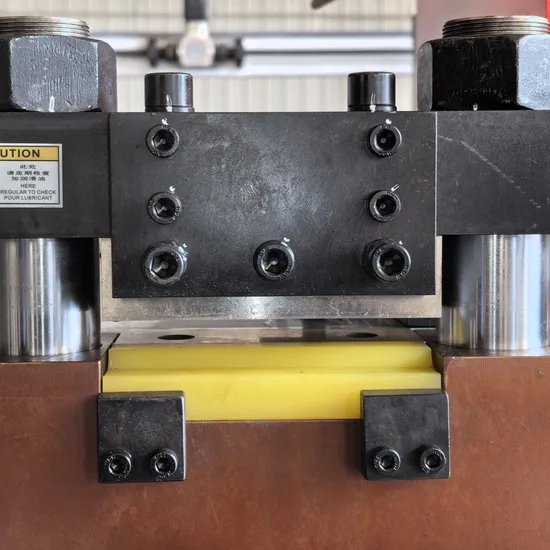

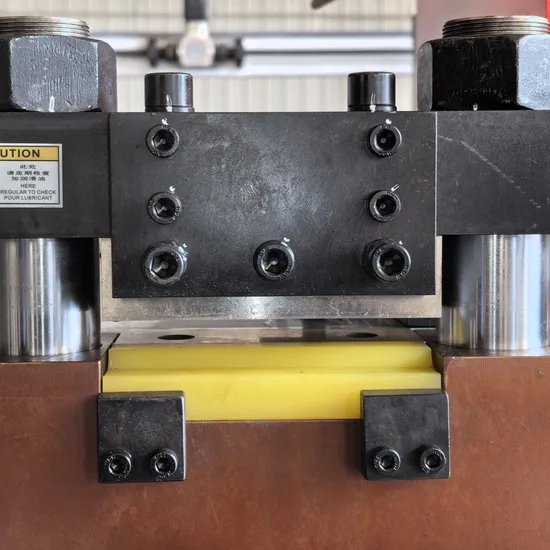

1. Cutting unit:

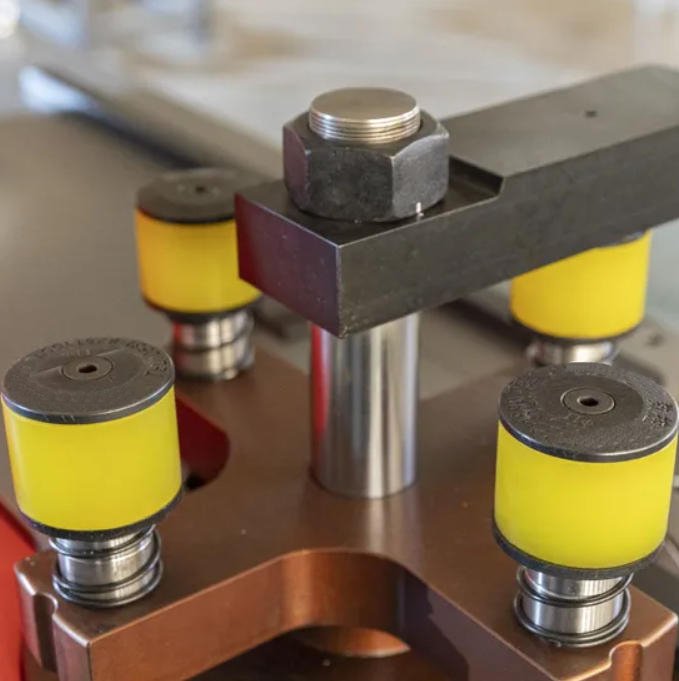

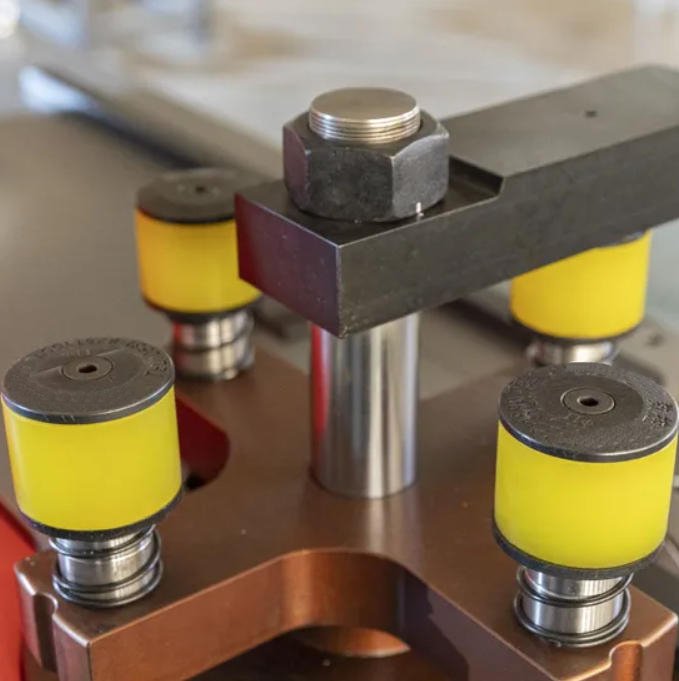

2. Punching unit:

3. Bending unit

Detailed Parameters:

Function | Item | 303U-3-C |

Punching | Max. Punching Force (KN) | 300 |

Punching Diameter Range (MM) | Ø4.3-Ø25 | |

Max. Thickness (MM) | 12 | |

Max. Width (MM) | 160 | |

Shearing/Cutting | Max. Shearing Thickness (MM) | 12 |

Max. Shearing Width (MM) | 160 | |

Vertical Bending | Max. Bending Force (KN) | 300 |

Max. Thickness (MM) | 12 | |

Max. Width (MM) | 160 | |

Horizontal Bending | Max. Width (MM) | 100 |

Max. Angle (Degree) | 90° | |

Out Dimension | MM | 1800 * 1400 * 1480 |

Power | KW | 3 * 4kw |

Weight | KG | 1420kg |

CNC Precision | Bending Precision | ±1° |

Repeat Bending Precision | ±0.3° |

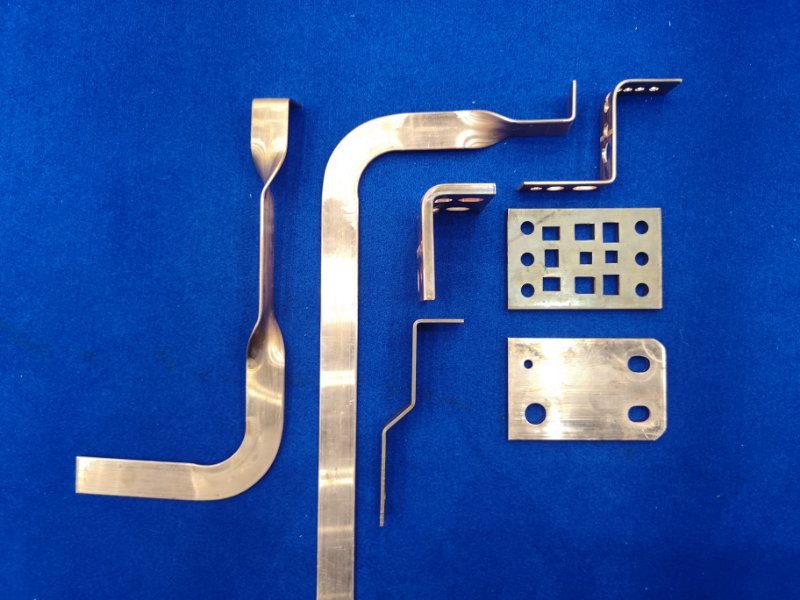

Samples of Best Quality Copper/Aluminum Busbar Fabrication Machine:

Factory:

Hot Tags: best quality copper/aluminum busbar fabrication machine,

Hot Tags: cnc busbar machine, 3 in1 busbar machine, busbar bending machine, busbar punching machine, busbar cutting machine, copper busbar bending machine, cnc bending machine, cnc punching machine, bending machine, busbar machine, copper busbar machine, cutter machine, machine bending, China, suppliers, manufacturers, factory, price

LT Busbar Machine Videos:

FAQ – Best Quality Copper/Aluminum Busbar Fabrication Machine (3 in 1)

1. What processes can this 3-in-1 busbar fabrication machine perform?

The machine integrates three functions: punching, shearing (cutting), and bending. Each unit can be operated independently.

2. What materials can the machine process?

It is suitable for processing copper and aluminum busbars within the specified width and thickness range.

3. What is the maximum punching force?

The maximum punching force is 300KN.

4. What is the punching diameter range?

The punching diameter range is Ø4.3mm to Ø25mm.

5. What is the maximum busbar size for punching?

The punching unit supports a maximum thickness of 12mm and a maximum width of 160mm.

6. What is the maximum cutting capacity?

The shearing unit can cut busbars up to 12mm in thickness and 160mm in width.

7. What is the maximum bending force?

The vertical bending unit provides a maximum bending force of 300KN.

8. What is the maximum busbar size for bending?

Vertical bending: up to 12mm thickness and 160mm width. Horizontal bending: maximum width of 100mm and maximum bending angle of 90°.

9. What is the bending accuracy?

The machine offers bending precision of ±1°, with repeat bending accuracy of ±0.3°.

10. What is the total power of the machine?

The power configuration is 3 × 4kW hydraulic systems for the punching, cutting, and bending units.

11. What are the machine dimensions and weight?

The overall dimensions are 1800mm × 1400mm × 1480mm, and the total weight is approximately 1420kg.

12. Is each unit (punching, shearing, bending) adjustable?

Yes. Each unit can be adjusted separately to reduce setup time and improve processing efficiency.

13. What industries commonly use this busbar fabrication machine?

It is widely used in electrical panel manufacturing, switchgear production, transformer workshops, and power distribution system fabrication.

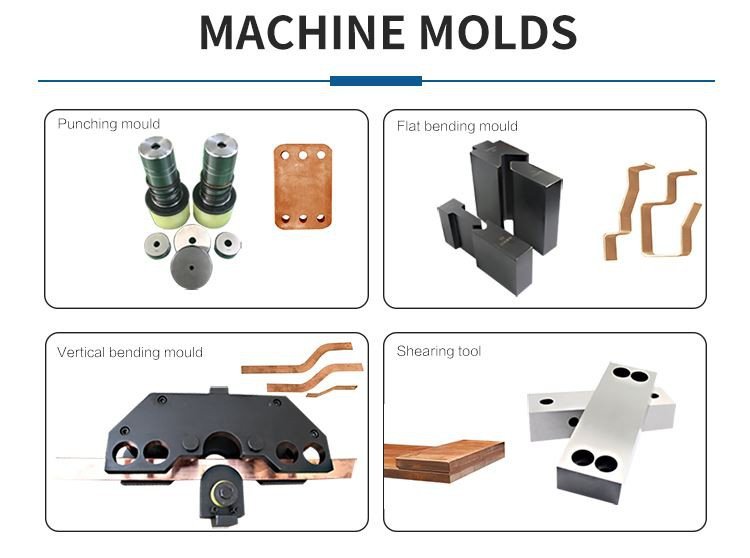

14. Does the machine support quick mold changes?

Yes. Punching molds can be replaced according to different hole sizes and production needs.

15. How can I request pricing and detailed technical support?

You can contact our sales or technical team to receive updated quotations and product documents.

3 in 1 busbar fabrication machine, copper aluminum busbar processing machine, hydraulic busbar punching shearing bending machine, multifunction busbar fabrication equipment, industrial busbar processing machine + Hot Tags:

3 in 1 busbar fabrication machine, copper aluminum busbar processing machine, hydraulic busbar punching shearing bending machine, multifunction busbar fabrication equipment, industrial busbar processing machine, busbar punching cutting bending machine, combined busbar machine, copper busbar fabrication machine, aluminum busbar fabrication machine, electrical busbar processing equipment, heavy-duty busbar fabrication system, high-precision busbar bending machine, copper bar punching and cutting machine, manual and hydraulic busbar bending equipment, switchgear busbar fabrication machine, power distribution busbar processing machinery, electrical panel busbar fabrication equipment, three-station busbar machine, integrated hydraulic busbar machine, workshop busbar processing equipment, copper bar forming and bending system, busbar workshop production machine, compact multifunction busbar processor, copper strip processing machine.