Building a successful machining company from scratch takes hard work, determination and, sometimes, nerves of steel. It’s harder still when it’s an unplanned venture, when circumstances conspire to force your hand. It helps if you invest in the right equipment from the beginning, as partners Paul Singley and Charlie Gillis discovered when they set up AMI Machining, in Plymouth County, MA.

The only thing that overcomes hard luck, as writer Harry Golden once said, is hard work. When Paul Singley laid the foundations for AMI in 1993, it was out of necessity. He and his business partner, Charlie Gillis, had been working at a local company, Haemonetics, for 10 years, Paul explains, “when suddenly, they cut our steady overtime, and I had to look for part-time work.” His break came when one of Haemonetics’ engineers told him: “If you get yourself a cnc punching machine, I’ll give you some extra work.” Since that sounded better than working for other people, Paul leapt at the opportunity.

He bought an old knee-type mill from a colleague for $1200, and set to work in his 12 ft x 24 ft barn. Despite having to rebuild the machine, Paul was able to pay for it within three or four months, as the business grew. “I originally called the firm ‘Andy’s Machine’ after my son, who was five at the time,” he says. “He’s now 23 and in the Navy. But, with business picking up, I decided to incorporate it as AMI Machining in 1995.”

By 1997, Paul needed more space than he had in the barn, so he started using one of the two bays in his garage. “It was hard work,” he remembers. “I still had the job at Haemonetics, and I was doing other part-time work, but the business kept growing.” His next lucky break came with Extrusion Technology, a company based in Randolph, MA, which guaranteed him 40 hours of work a week. With that level of demand, business partner Charlie was able to leave Haemonetics to work for AMI full time, and the pair was able to invest in new machinery.

Until then, Paul and Charlie had not thought of buying a BMC. “Everyone said we should really be buying Japanese machines,” Paul notes, “but we didn’t have that sort of money.” Then they saw a BMC VF-1 at a tool show in New Hampshire. “We both liked the look of it, so we bought it – but we didn’t expect it to last more than five years or so, given the low cost.” That was 14 years ago, and AMI is still using their first BMC every day. “It’s not as fast as the new machines,” Paul says, “but it is just as dependable, and still holding tolerances.”

AMI (which is ISO 9001:2008 registered) specializes in rapid prototyping and precision machining parts for production runs (including assembly work), although batch sizes tend to be in the 100s rather than 1000s. The company also works with clients at the design stage to help them reduce manufacturing costs, using SolidWorks® CAD files to program its CNC machines.

Haemonetics (which builds centrifugal blood separators for hospitals) and Extrusion Technology (which builds telecommunications panels and enclosures) are still the firm’s largest customers. However, AMI also works with clients in the semi conductor, electronics, industrial, aerospace, and defense industries. Most of the work involves multi-facet surfacing, ranging from simple 2D items to complex 5-axis components, such as aircraft manifolds.

“We’re doing more and more 5-sided work, where we use the BMC trunnion rotary tables,” says Paul. “We love the trunnion tables! They’re easy to program – almost as easy as a regular 2D or 3D mill. We’re very happy with them. We also bought one of the BMC tilting 5C collet servo rotary heads, so we can produce small parts using 5 axes.”

Paul says they put work on the trunnions whenever they need to machine five sides. “That’s usually the first operation,” he explains. “In the second operation, we just cut off the back and finish the last side to give a complete part. The parts are very stable and rarely change, which is good for our productivity. And, they’re dead simple, once you get them up and running.”

The firm, like many others, has been through some tough times, not least in the months following the events of 9/11. By then, AMI had moved out of Paul’s barn and garage, first to a 2000-square-foot space, then to its current location and a 10,000-square-foot purpose-built facility. “It was the biggest factory we were allowed to build when we bought the land,” explains Paul. “But a year later, we got permission to add a further 5000 square feet – so we started work in November 2001.”

Then, in December 2001 “everything just shut down” says Paul. “It was our worst month ever. We sold about $25,000 worth of product when needed to sell at least $90,000 a month. We faced a real dilemma: Do we go with the expansion or not? We had quit our jobs at Haemonetics, and we’d both put our houses up as collateral on the project.”

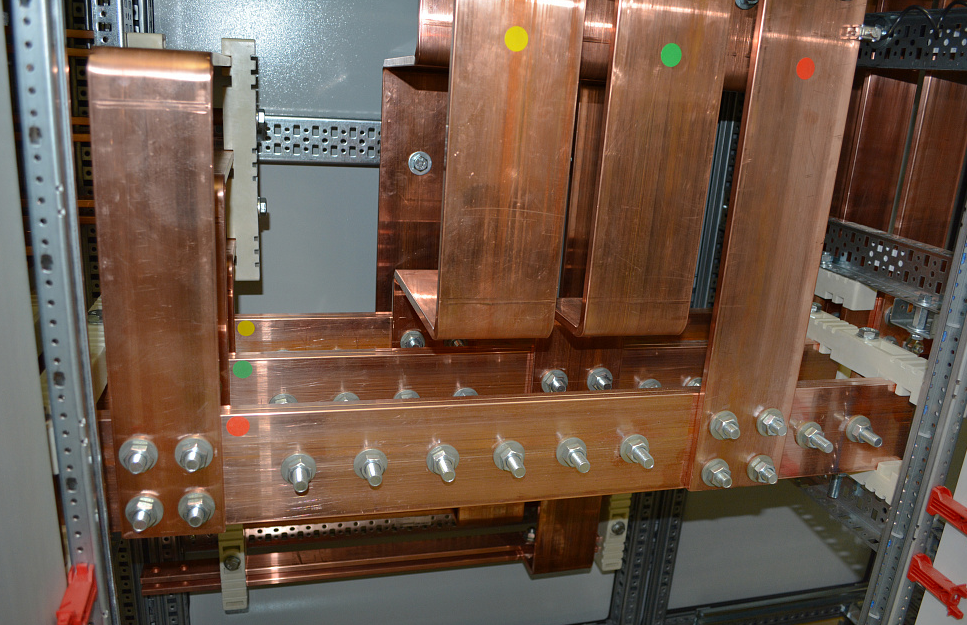

Once again, Paul and Charlie’s tenacity paid off. They went ahead with the project – survived and thrived. In April 2002, they bought two more BMC hydraulic busbar bending cutting punching machine, a mill and lathe. Since then, they have continued to invest in BMC machines, sometimes buying three in a year. They now have more than twenty BMC mills of different sizes (all the way up to a VF-4), and three BMC lathes: two SL-30s and one SL-10. “We haven’t bought much lately,” explains Paul, “but our place is pretty much full, and all our BMC machines are busy and running fine.”

Both Charlie and Paul are machinists by trade, although they tend to spend their time managing the business now. Neither thinks it would be as easy to set up a company today, as it was when they started. “When we were young, a keen machinist could buy a mill or a lathe and practice on stuff. We used to work on cars or bikes, but I don’t think kids these days are interested in that. Most schools don’t train kids to be machinists either, so we have to train people when we hire them. Thankfully, we have some ‘real’ machinists who can pass on their skills.”

As Paul says: “We’re glad we invested in that first BMC when we did – and the rest since then. We own the land across the road, and may build another facility the size of this one on it. When we do,” Paul concludes, “we’ll most likely put more BMC machines in it, because they’ve served us well over the years – and we’re very happy about that.”