HQ40-BC CNC Copper Busbar Cutting Bending MachineProductCNC Copper Busbar Bendin

HQ40-BC CNC Copper Busbar Cutting Bending Machine

Product: CNC Copper Busbar Bending Machine

Serial: HQ40-BC

Main Function: To cut and bend copper/aluminum busbars, etc.

Main Feature:

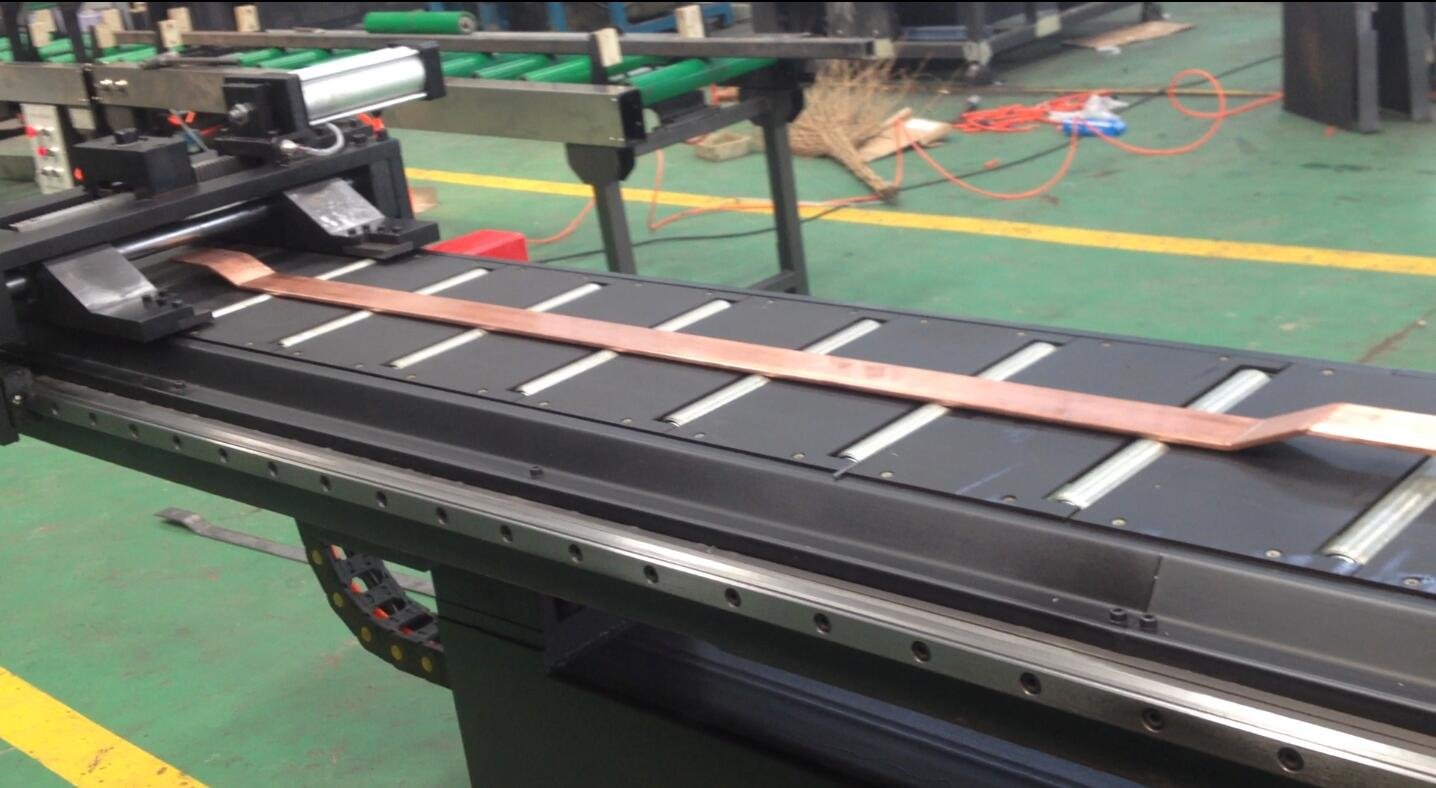

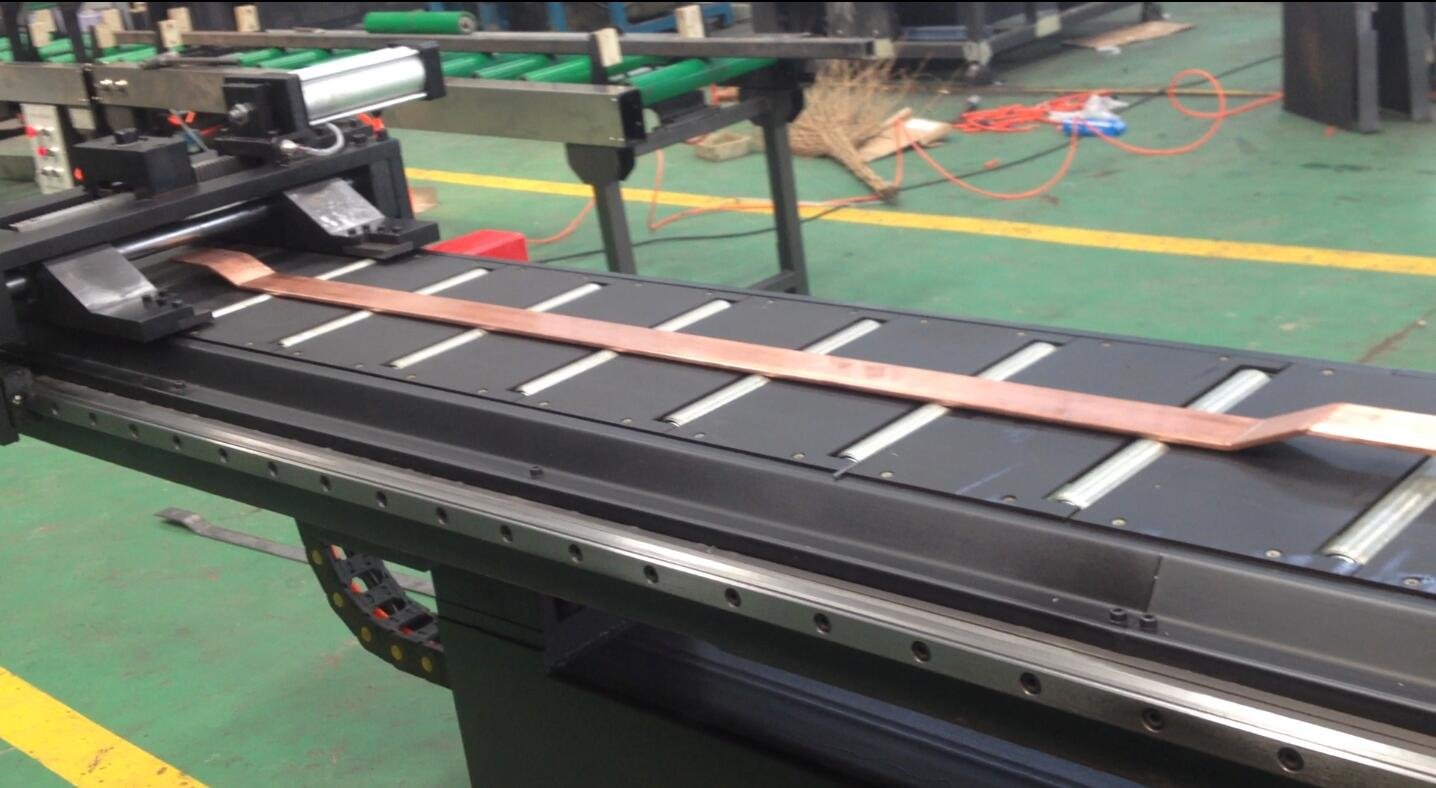

HQ40-BC CNC copper busbar cutting bending machine has two units: cutting and bending. It can handle different specifications of copper busbars for shearing and "Z" type bending.

Cutting unit: single-blade shear, flat notch, no burr, max width 210mm, thickness 10mm.

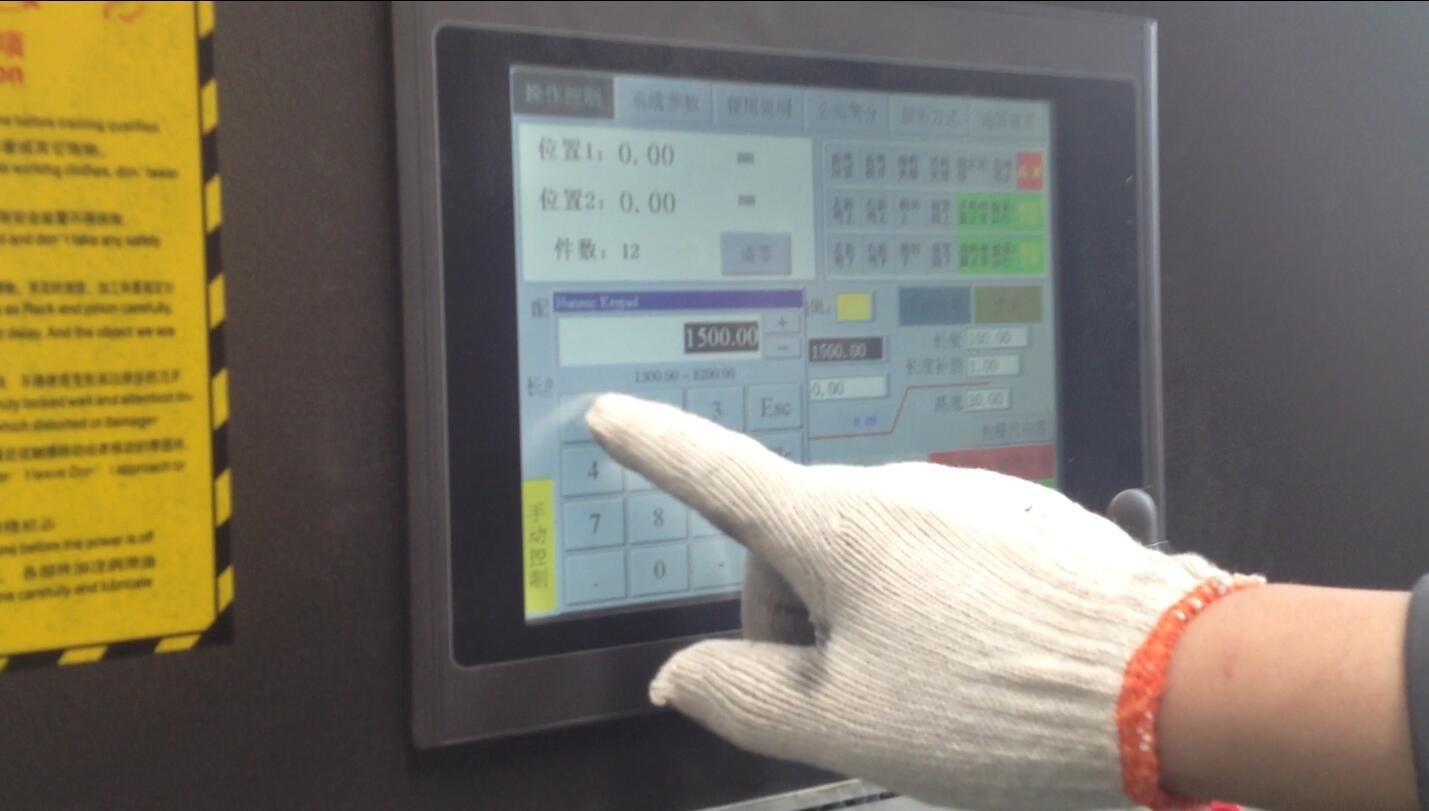

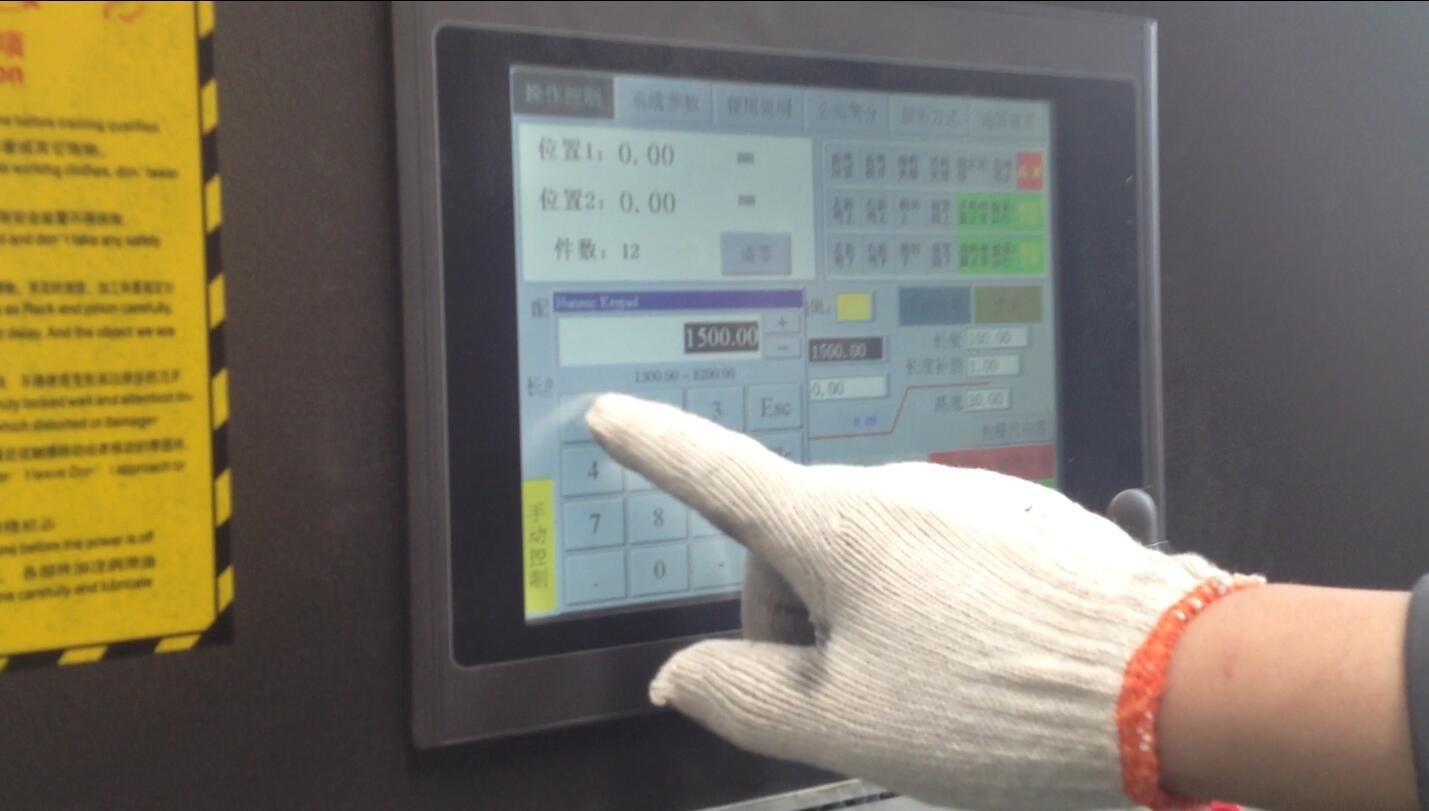

"Z" bending forming unit: CNC adjustable unit, closed-loop displacement sensor feedback, max width 210mm, thickness 10mm, length 3200mm.

Technical Parameters:

Video:

HQ40-BC model in 1 manual hydraulic busbar machine FAQ:

Q1: What is the main function of the HQ40-BC busbar machine?

A1: The HQ40-BC CNC Copper Busbar Cutting Bending Machine is designed to cut and bend copper and aluminum busbars efficiently, providing high precision for shearing and "Z" type bending operations.

Q2: What are the main features of the HQ40-BC?

A2: The machine includes two main units: a cutting unit with single-blade shear that produces flat, burr-free cuts up to 210mm wide and 10mm thick copper, and a CNC bending unit with displacement sensor feedback, capable of "Z" type bending for copper up to 210mm wide, 10mm thick, and 3200mm long.

Q3: What are the technical specifications?

A3: The HQ40-BC technical parameters are: Max Punching Force 300 KN, Max Process Width 210 mm, Max Process Thickness 10 mm, Max Process Length 3200 mm, Max Tensile Height 30 mm, Overall Size 9600 × 700 × 1400 mm.

Q4: What types of busbars can be processed?

A4: The machine can process copper and aluminum busbars, handling various specifications for cutting and "Z" type bending, suitable for electrical and industrial applications.

Hot Tags: CNC busbar cutting bending machine, copper busbar bender, aluminum busbar processing, hydraulic busbar machine, automatic busbar cutter, precision busbar bending, industrial busbar fabrication, electrical busbar equipment, Z-type busbar bender, high-precision copper bending

CNC busbar cutting bending machine, copper busbar bender, aluminum busbar processing, hydraulic busbar machine, automatic busbar cutter, precision busbar bending, industrial busbar fabrication, electrical busbar equipment, Z-type busbar bender, high-precision copper bending, CNC busbar fabricator, multi-function busbar machine, copper and aluminum bending, heavy-duty busbar cutter, CNC hydraulic busbar bender, copper busbar shearing machine, automated busbar forming, Z-shape busbar forming, high-efficiency busbar machine, industrial copper bending equipment